Pendant Push Button For EOT Cranes and Hoists

Data based Pendant for EOT Cranes and Hoists using 4 Core Data Cable

Upto 4 Motions & 2 Speeds

Fully Assembled & Highly Configurable. Operates Upto 40 Relays.

For Main Hoist,Auxillary Hoist,Cross travel and Long travel Motions.

Flame Proof Pendants also available.

*Customized and Standard Pendant Controls.

*All Anand Data Pendants are Made in India.

*CraneSCADA compatible.

Pendant Push Button Operation.

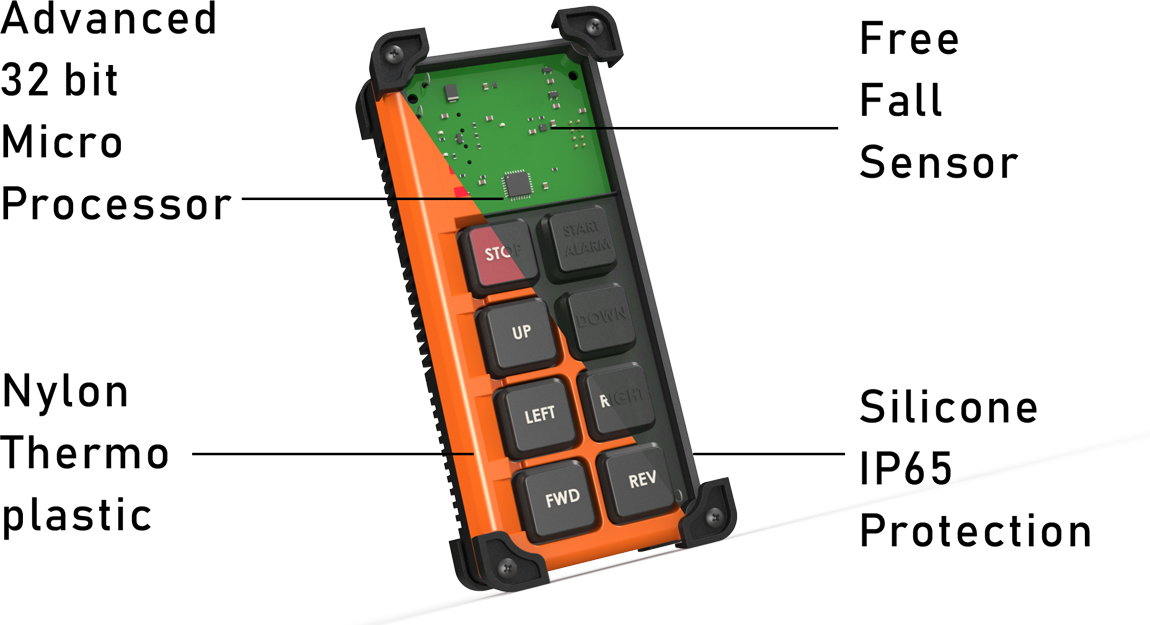

Anand Data Pendants (ADP) are used for the manual control of industrial equipment such as EOT Cranes and Hoists by means of contactors or Variable Frequency Drives.

Industrial Machines particularly EOT Cranes & Hoists can be easily controlled from the factory floor. Various combination of switches can be implemented using single speed , double speed or potentiometers . ADPs feature 2 , 4 , 6 , 8 , 10 or 12 Push Buttons in a two column arrangement for ergonomic and fatigue-free operation.

Only 4 core 0.25sq mm cable is required for any number of buttons.

The push buttons have a silicone top layer to protect the button labels.

Size Difference Between Anand Data Pendant and Competitors

Two Button Push-Button Crane Pendant

Two Button Push-Button Pendant comprises of two operational buttons. There is only an up and down direction button for an operating crane.

Four Button Push-Button Crane Pendant

Four Button Push-Button Pendant comprises of Start, Stop, Up, and Down button configurations for controlling an EOT cranes.

Six Button Push-Button Crane Pendant

Six Button Push-Button Pendant comprises of On, Off, Up, Down, East, and West button configurations for controlling purposes.

Eight Button Push-Button Crane Pendant

Eight Button Push-Button Pendant comprises of On, Off, Up, Down, East, West, North, and South button configurations for controlling an EOT cranes.

Ten Button Push-Button Crane Pendant

Ten Button Push-Button Pendant comprises of On, Off, Up, Down, East, West, North, South, One Speed Version, and Two Speed Version button configurations for controlling an EOT cranes.

Anand Push Button Crane Pendant Stations developed using modern embedded electronic circuits and advanced certified software.

Smaller than the current pendants, faster, secure, flame proof,cheaper,Servicable,Easy to operate.

Crane Pendant can be easily Installated and Replaced on Field

Crane Pendant Station

Know all about Pendant Station For Crane. The crane pendant is one of the most frequently handled parts of a EOT crane. Understanding this seemingly inconspicuous component and handling it right can save crane users a tidy sum. Crane Pendant Demystified!

What are crane pendants?

Crane pendant refers to the part of the crane that is used to control the hoist in an overhead crane. It is also known by other names such as crane control unit or crane pendant station. It is perhaps the most important part of the crane and the one most often replaced. It is also the first place a crane inspector or maintenance person would check in case of breakdown. The term crane pendant is devised– and generally used – to describe control units wired into the electronic crane mechanism. The unit is attached to a long wire and dangles from the overhead crane – like a pendant. It is also referred to as pendant control or pendant control unit. It draws power from the same electric source that powers the crane itself.

How does a crane pendant work?

A crane may be operated by an operator seated in a cab and guided by a person on the ground or it may be controlled from the ground using a push button or lever control. This control unit may be wired to the crane itself or – as in the case of many contemporary cranes – it may be a remote radio unit. A wired push button pendant that is connected to the hoist and dangles down from the overhead crane is used by an operator to control the crane. The operator walks alongside the crane as it traverses the runway. He can control the lifting and lowering of the load using the pendant. Until about a decade ago, all overhead cranes were operated by wired pendant controls.

Pros and Cons of Pendant Controls

The most significant benefit of wired pendants is perhaps its connectivity – since the pendant is wired to the

crane, there is virtually no scope for interruption in electric current – and consequent interruption in operation.

Moreover, since pendants are suspended from the hoist, there is no possibility of accidentally dropping the control

or misplacing it. Pendant controls also do not require charging or battery replacement since they are powered by

crane electrification system.

Perhaps the only significant disadvantage of pendant systems is that it places the operator within the periphery

of the crane operation area. This can be potentially risky – particularly with heavy-duty hoist cranes where an

accidental load drop could harm the operator and may be potentially fatal. Moreover, as the operator walks along

the runway, observing the crane and ensuring safe and uneventful picking and lowering of the load, he is exposed

to the risk of tripping, slipping, or bumping into obstacles. Another potential risk in using wired pendant

controls is that the wire – being directly attached to the crane – can be caught up in the crane mechanism,

causing damage not only to the control system but also to other crane parts or at the very least resulting

in costly downtime.

Remote Controls

Why to use pendant push buttons

Pendant controls or simply crane pendants are crane control devices wired into the crane mechanism. These devices are used to control crane operations from the ground – eliminating the need for guidance by ground personnel. Many present day cranes use radio-operated control devices that can control operations from afar. Both types of controls have their benefits and risks – so selecting the right type of pendant is an important part of your decision to purchase an overhead crane. CraneSCADA offers guidance in control and monitoring of cranes. Contact us now to know more.

Product List of Pendant

| Sr. no. | Product Name | Description | Part Number | Images |

|---|---|---|---|---|

| 1 | Pendant 2B1S | 2 Button 1 Speed Pendant | Pendant2B1S | |

| 2 | Pendant 4B1S | 4 Button 1 Speed Pendant | Pendant4B1S | |

| 3 | Pendant 6B1S | 6 Button 1 Speed Pendant | Pendant6B1S | |

| 4 | Pendant 8B1S | 8 Button 1 Speed Pendant | Pendant8B1S | |

| 5 | Pendant 10B1S | 10 Button 1 Speed Pendant | Pendant10B1S | |

| 6 | Pendant 12B1S | 12 Button 1 Speed Pendant | Pendant12B1S | |

| 7 | Pendant 2B2S | 2 Button 2 Speed Pendant | Pendant2B2S | |

| 8 | Pendant 4B2S | 4 Button 2 Speed Pendant | Pendant4B2S | |

| 9 | Pendant 6B2S | 6 Button 2 Speed Pendant | Pendant6B2S | |

| 10 | Pendant 8B2S | 8 Button 2 Speed Pendant | Pendant8B2S | |

| 11 | Pendant 10B2S | 10 Button 2 Speed Pendant | Pendant10B2S | |

| 12 | Pendant 12B2S | 12 Button 2 Speed Pendant | Pendant12B2S | |

| 13 | Pendant 14B2S | 14 Button 2 Speed Pendant | Pendant14B2S |

Pendants for Cranes and Hoists

Anand Pendant Controls use the most advanced micro controllers

No Bulky 16-24 Core cable.

Operate any number of motions with only 4 core Anand Data cable.

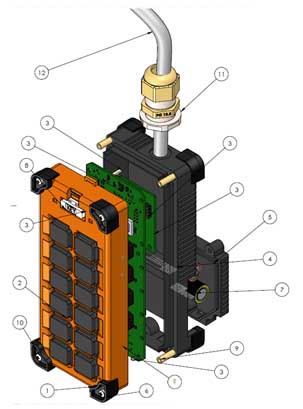

Assembly & Construction of Crane Pendants

Push Button Assmebly

Push Button Assembly in crane Pendant which comprises of NO NC Push Buttons , Soldered onto the PCB. It is made from the fiberglass polyester material by molding process. This type of material is very highly resistant to shock, arcing, and tracking.

Connector Terminal

The 4 Pin Connector Terminal is given inside the pendant box .It can handle upto 10 amps.

No Return Springs

Return Springs are assembled into the button.

Core Cable

It consists of 4 core cable, which will provide communication between the Control Panel of the EOT crane and push-button pendant.

Plastic Enclosure

The enclosure is made up of plastic material. It is usually a yellow enclosure for safety purposes. It is sealed tightly, that can resist the water from damaging the internal part.

Emergency Key

An additional Mushroom type emergency key or Magnetic Emergency key is provided if we urgently want to stop the operation of the EOT crane.

Features of Push Button Pendant Box

-

It has an enclosure rating of NEMA (National Electrical Manufacturers Association) 4x.

-

It provides easy operation; also offers easy grip so that we can hold a device from one hand also.

-

It offers resistance to shock and corrosion.

-

It offers single or two-speed operation.

-

We can use a one-button operation at a time. When we want to use a crane to move in a particular direction, then we have to keep the button pressed continuously, until the crane reached its desired point.

-

It has a full cover body of gasket material, so it will be protected from harmful contaminants.

-

It offers self-lifting pressure for wire connection, which offers easy wiring.

-

It has an internal strain-relief post.

-

Momentary or maintained contact.

-

It comprises of two directions mechanically interlocked in pair buttons.

-

It has a safety yellow enclosure for indoor and outdoor applications.

-

Able to work on AC (Alternating Current) power as well as DC (Direct Current) power.

-

There is a ground connection at the entrance area of the cable.

-

It has a compact size.

-

It offers up to five-speed points and eight common circuits, which are design for each direction.

-

The cable grip clamps present between the cable and enclosure that provides the sealed connection which is waterproof.

-

The circuit of the push-button pendant is pre-wired for all the switched for simple wire connections.

-

The button functions are easy to read.

-

It has a protection rating of IP65 (Ingress Protection).

Available Options for Push Button Pendants

-

Duplex stations

-

Handles

-

Selector Switches

-

Pilot Lights

-

Push or Pull Buttons

-

Toggle Switches

-

Inter-connecting conduit boxes

-

Stainless steel wire mesh cable grip

-

J-Box mounting for an additional switch or LED

-

On/off key switches

-

Blank for covering the buttonhole

Conclusion

The push-button is the best solution for operating the EOT cranes while lifting and handling the load. It reduces the manpower as sometimes driver is needed to operate the cranes. Push-button pendant is specifically designed for EOT cranes and critical industrial applications. The wired connection push-button pendant will offer reliability and stability.

Anand Crane Pendant Technical Data Specifications

|

|||||

| Mechanical Specifications: | |||||

| Push Button | Single Step | Double Step | |||

| -Electrical Life | 20,000 Cycles | ||||

| -Actuation Force | 490 Grams | 1st Step:600 Grams 2nd Step:1150 Grams |

|||

| -Button Type | Tactile | ||||

| Operating Temperature | 0 to 75℃ | ||||

| Led Indication | Led 1:Power | ||||

| Led 3:Emergency | |||||

| Led 4:Receiver Acknowledgment | |||||

| Electrical Specification of Transmitter: | |||||

| Operating Temperature | 0-60℃ | ||||

| Removable Config Card | Yes.No Need of Copier device. | ||||

| Emergency Stop | Magnetic | ||||

| Electrical Specification of Receiver: | |||||

| Number of Relays | 2 to 18 Relays | ||||

| Relay Rating | 250Vac 10Amperes/30Vdc | ||||

| No Load Power Consumption | 0.1 Watts | ||||

| Main line Relay Indicator | Red Bright Light | ||||

| Power Supply | 110Vac/230Vac/ 12VDC – 40 VDC | ||||

| Tandem Operation | Yes(Configurable) | ||||

| Security Specification: | |||||

| Advanced Encryption Standard | 128 Bit AES Key | ||||

| Software Standard | Misra C Standard | ||||

| Auto Main Line Shutdown Idle Time | 10 Minutes(User Configurable) | ||||