DSL Busbars for Industrial Overhead EOT Cranes

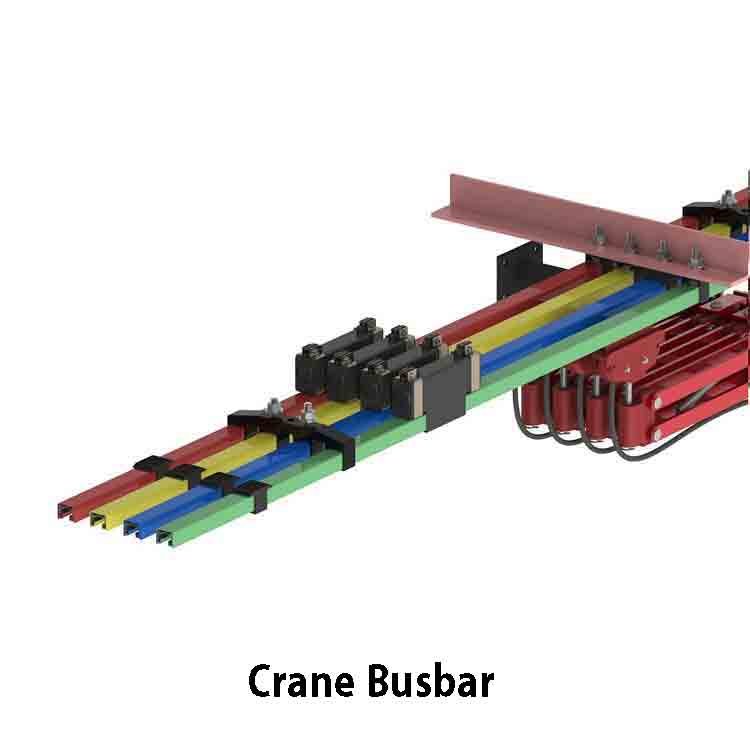

DSL Busbars are made up of highly electrically conductive metals and they distribute & carry power from a source to a destination or multiple destinations.They are used in EOT Cranes to supply power from the grid to the crane control panel.

Full Form of DSL busbar is Down Shop Lead.

When it comes to industrial overhead EOT cranes, power distribution is crucial for safe and efficient operation. DSL busbars provide a reliable and cost-effective solution for power distribution, allowing for smooth crane operation and minimizing downtime. Our DSL busbars are made with the highest quality materials to ensure maximum conductivity and durability.

In addition to improving power distribution, using DSL busbars can also help increase the overall efficiency of your crane operations. They are easy to install and maintain, and can help reduce energy consumption and costs.

If you're looking for a high-quality and reliable power distribution solution for your industrial overhead EOT crane, consider investing in DSL busbars. Browse our selection of DSL busbars today and find the perfect fit for your crane.

Overhead EOT Crane Shrouded DSL Busbar Manufacturer in India

To Manufacture DSL Busbars for EOT cranes requires significant investment in equipment ,time and skilled technicians. With decades of experience and facilities spread across India, Anand Systems Engineering has become the top Eot Crane DSL busbar manufacturer with over 1000+ businesses using different profiles of DSL busbars manufactured by us.

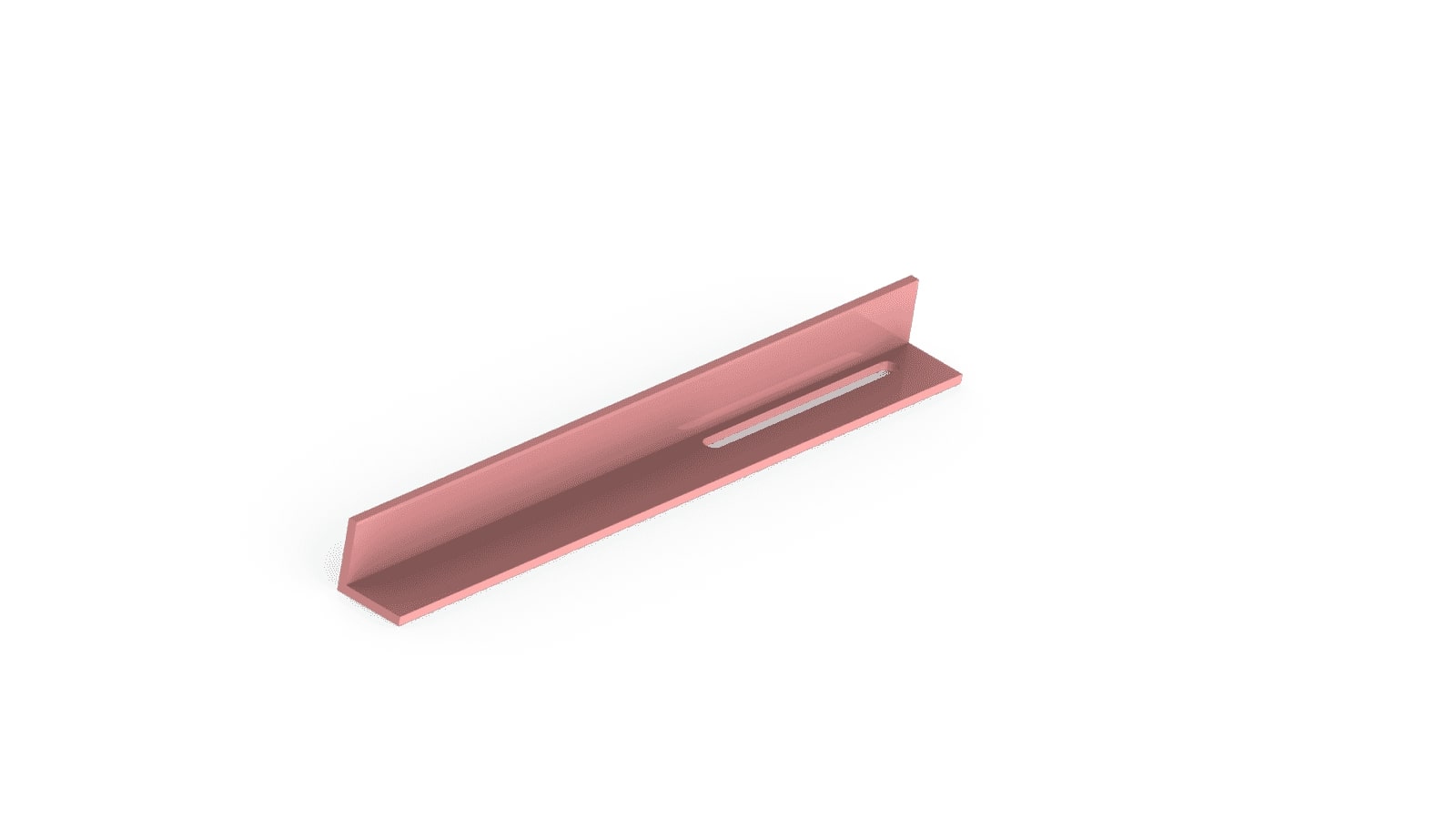

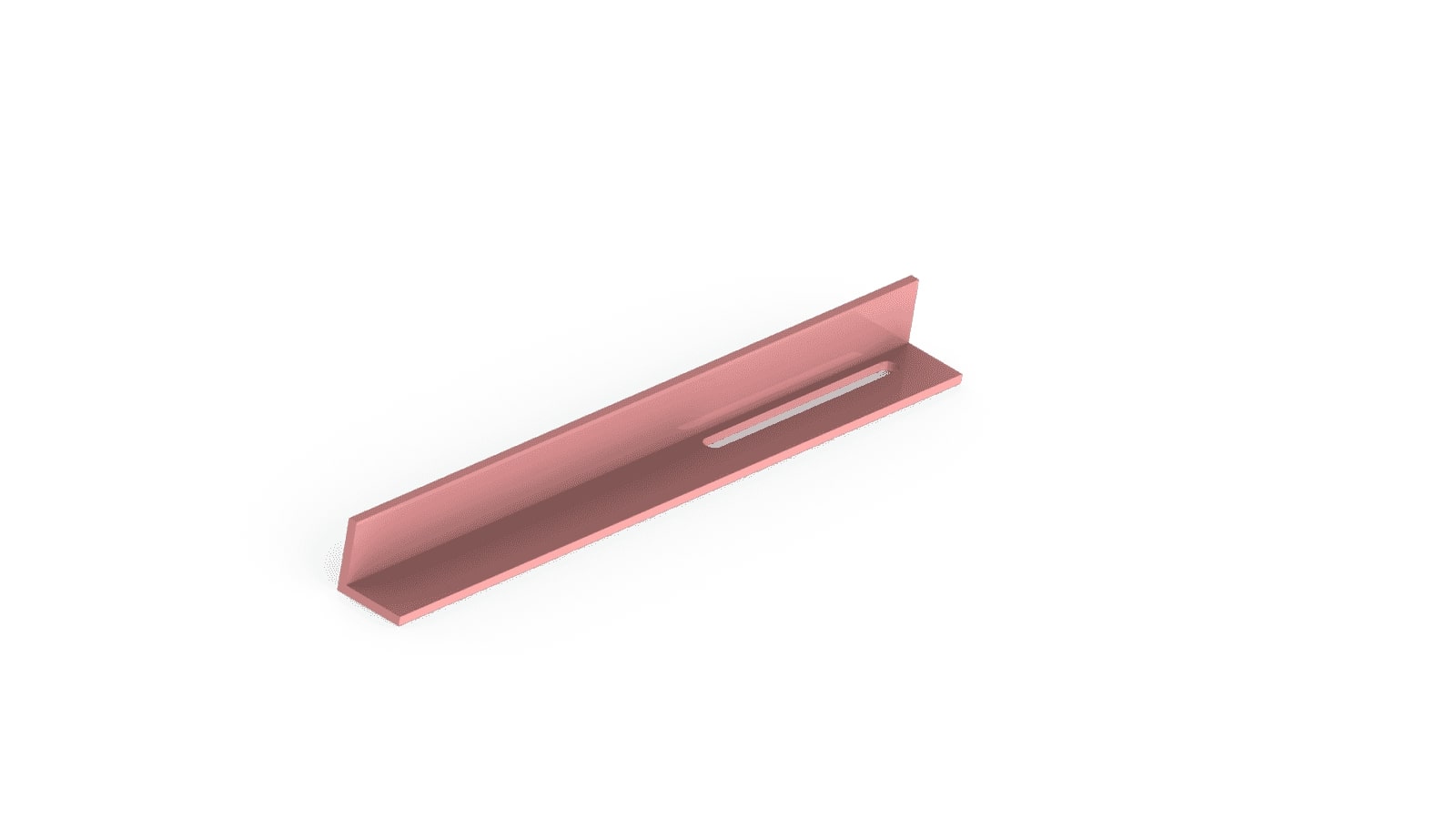

Different Profiles of DSL Busbars For Electric Overhead Cranes

DSL Busbar profiles reduce the overall weight of the system as compared to flat busbars and provide the cost benefit to the user.

Prefabricated Busbar Profiles are advantageous to flat busbars because profiles optimize the space of installation,

help make the installation easy. Long installation busbars should be using profiles to reduce the skin effect.

Depending upon the electrical frequency of the AC voltage, due to skin effect the AC current tends to flow near the surface

of the conductor. Hence areas of the busbar with low current density can be removed, thereby saving weight and cost.

The skin depth of copper busbar is 8.5mm at 60 hz frequency.

As the frequency of the AC voltage increases, the skin depth reduces. Using DSL busbar profiles helps reduce the effect

of skin depth by optimizing the areas of higher and lower current density and achieving better performance even when

utilizing less weight than flat busbars. Current density can be uniformly spread across the cross section of the profile.

A Guide to Choosing the Right Busbar: DSL, Safelink W, Safelink M, and Safelink V Explained

When it comes to electrical installations, choosing the right busbar is crucial. With the variety available in the market, it's easy to get confused. This guide aims to simplify your decision-making process by explaining the different types of busbars offered by us: DSL, Safelink W, Safelink M, and Safelink V.

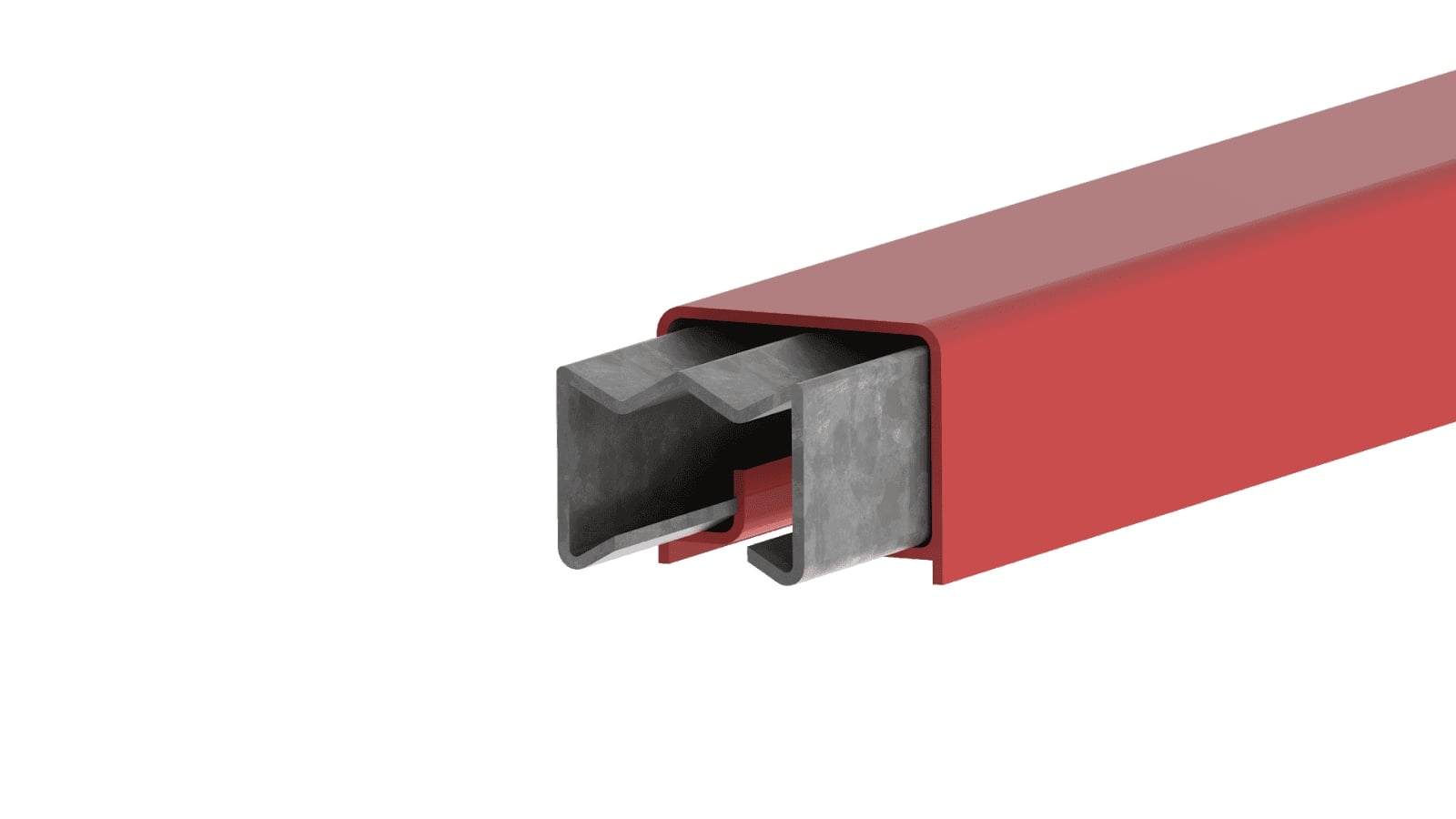

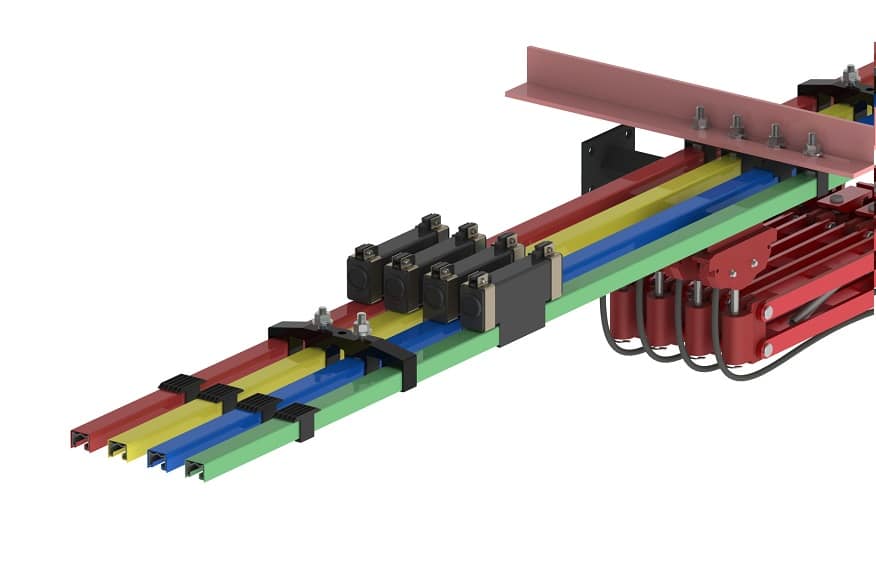

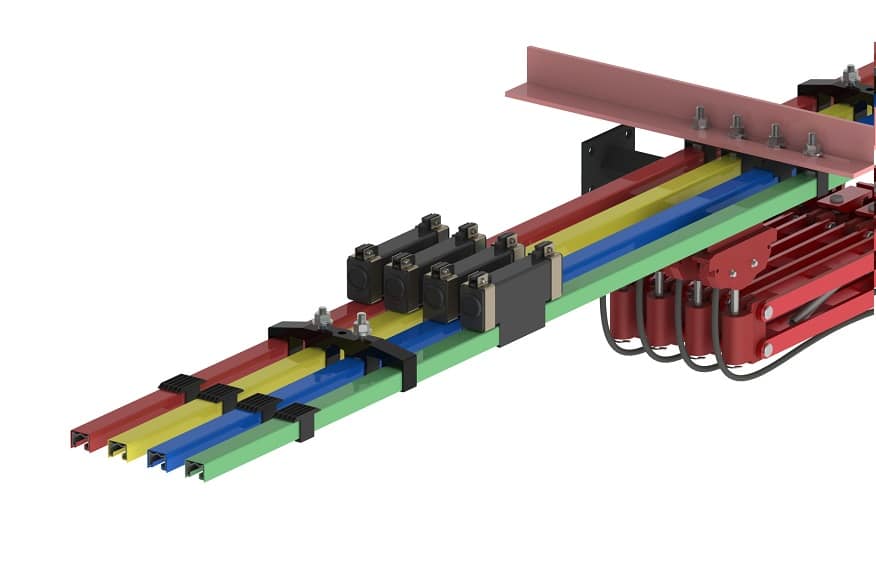

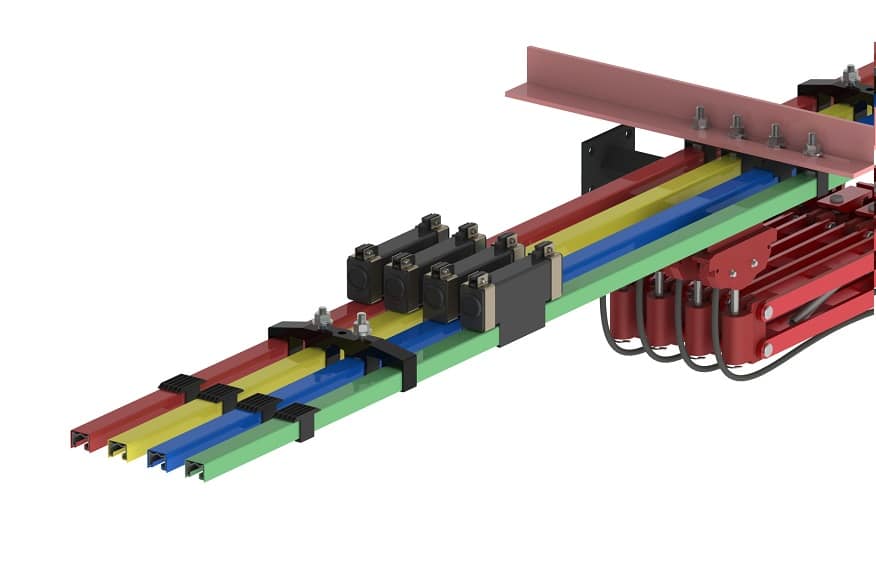

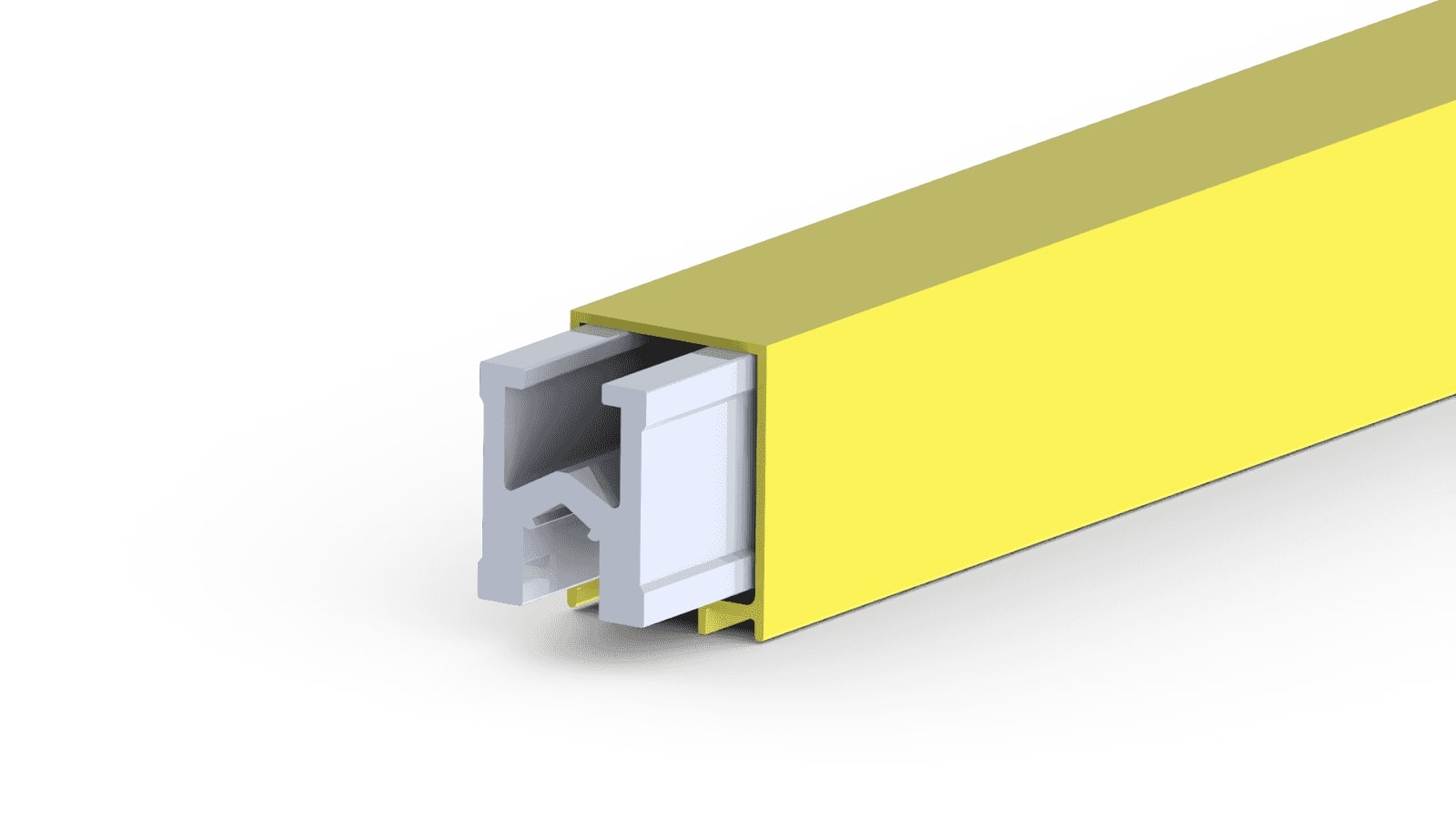

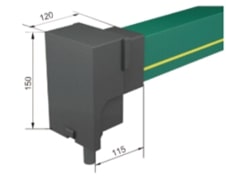

Shrouded DSL Busbar

DSL busbars are versatile, catering to various amperage needs, meter lengths, and materials. The amperage can range from 10 to 1250 Amps, meters from 4.5 meters to any desired length, and materials including GI, Copper, Aluminium, and Stainless Steel.

DSL Busbar Variants:

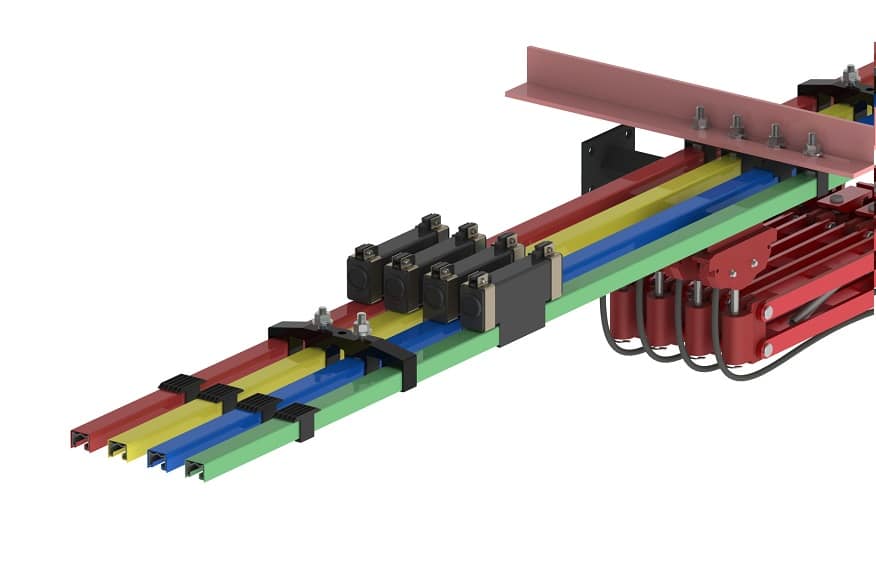

3 Phase DSL Busbar:

This configuration includes three busbars, each identified by a colored PVC sleeve (red, yellow, and blue).

4 Phase DSL Busbar:This version expands to four busbars, with an additional green PVC sleeve.

Safelink W DSL Busbar

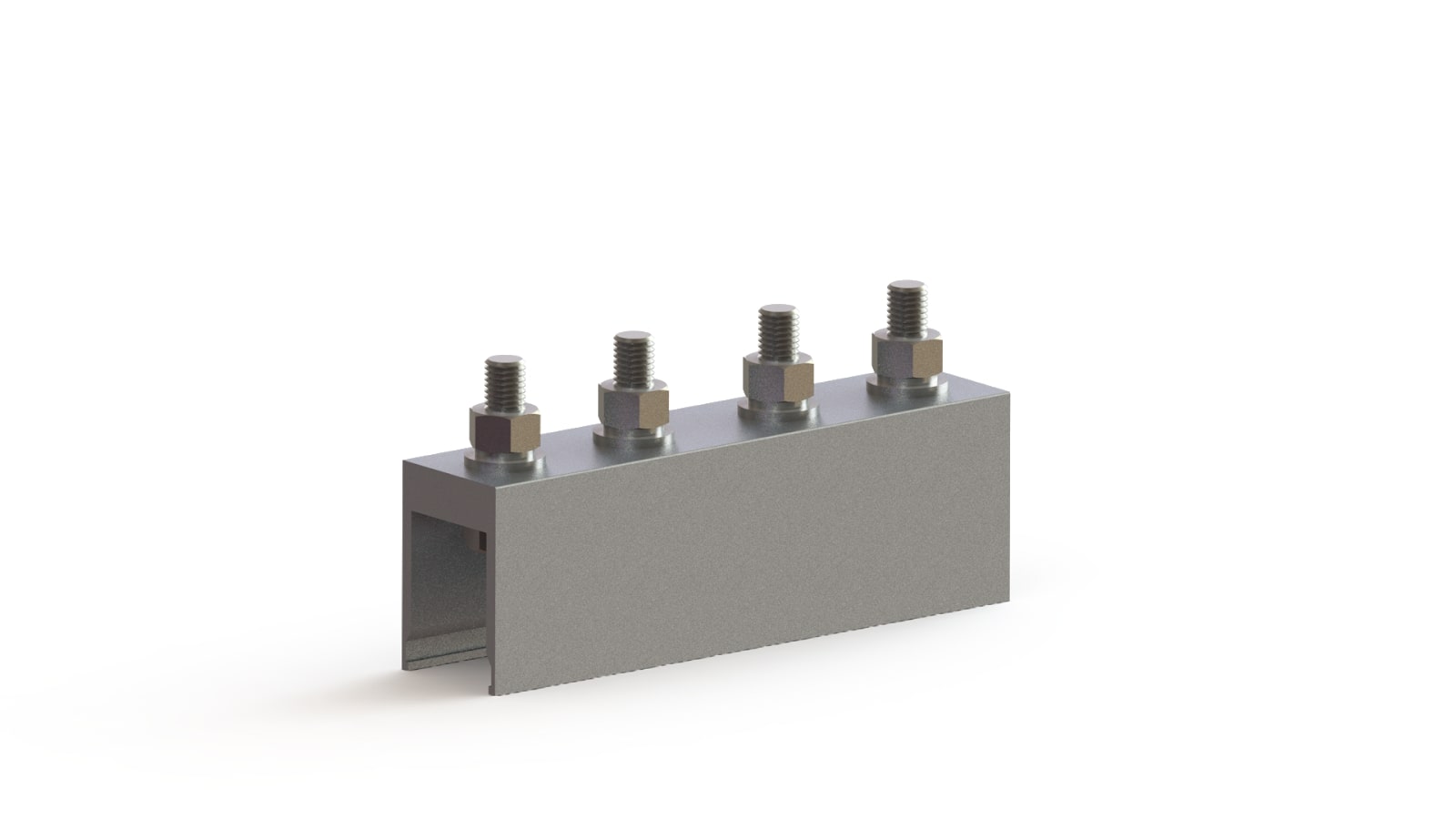

Safelink W DSL Busbar are bolted-joint busbars, making maintenance easy as only faulty sections need to be removed. They come in various configurations to suit different amperage requirements and materials like GI, Copper, and Aluminium.

Recommended Safelink W Busbars

SLW-100-RYBG-GI: 100 Amp, GI, 04 Bar, Bolted (W) Type, PVC Sleeves in Red, Yellow, Blue, and Green.

SLW-250-RYB-CU,G-GI: 250 Amp, Copper, 04 Bar, Bolted (W) Type, PVC Sleeves in Red, Yellow, Blue, and Green, with 3 Copper Busbars and 1 GI Busbar.

SLW-400-RYBG-ALU: 400 Amp, Aluminium, 04 Bar, Bolted (W) Type, PVC Sleeves in Red, Yellow, Blue, and Green.

Safelink M DSL Busbars

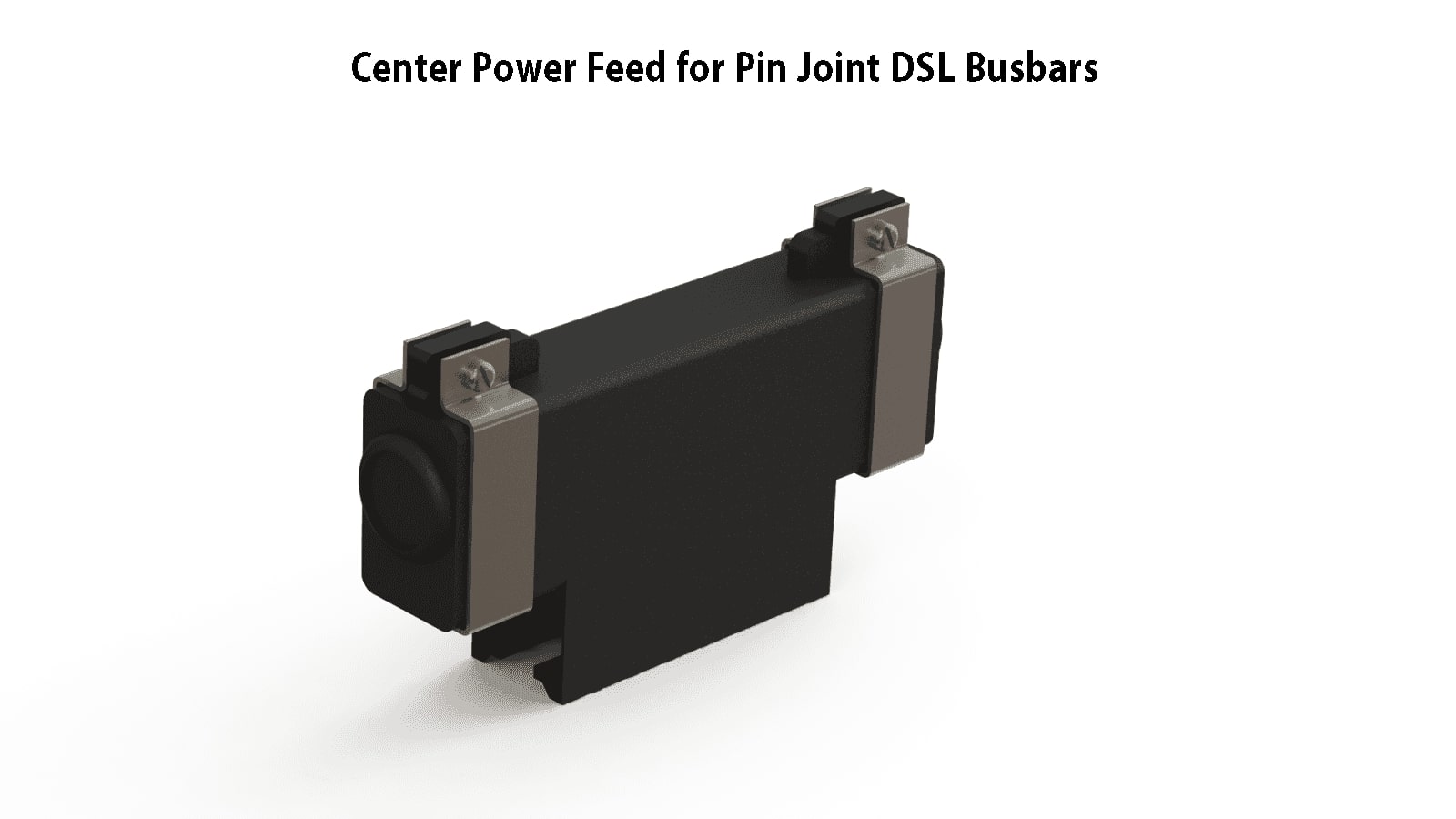

are pin-joint type, where sections are joined using pins and jointing tools. Although the installation is fixed, maintenance involves removing the entire busbar setup, making them suitable for specific applications.

Recommended Safelink M Busbars:

SLM-125-RYBG-GI: 125 Amp, GI, 04 Bar, Pin Type, PVC Sleeves in Red, Yellow, Blue, and Green.

SLM-315-RYB-CU,G-GI: 315 Amp, Copper, 04 Bar, Pin Type, PVC Sleeves in Red, Yellow, Blue, and Green, with 3 Copper Busbars and 1 GI Busbar.

Safelink V DSL Busbar

Safelink V busbars are heavy-duty, designed for high amperage applications. They come in both 3-bar and 4-bar configurations, offering flexibility for various setups.

Recommended Safelink V Busbars:

SLV-800-YYYG-AL: 800 Amp, Aluminium, 04 Bar, V Type, PVC Sleeves in Yellow, Yellow, Yellow, and Green.

SLV-1250-YYY-CU: 1250 Amp, Copper, 03 Bar, V Type, PVC Sleeves in Yellow, Yellow, Yellow.

How to Choose

Determine Amperage: Calculate the total amperage requirement for your application. Choose a busbar that comfortably handles the load with some margin for future expansions.

Consider Material: Decide between GI, Copper, Aluminium, or Stainless Steel based on your budget, conductivity requirements, and environmental factors.

Evaluate Installation Type: Choose between bolted-joint (Safelink W), pin-joint (Safelink M), or heavy-duty (Safelink V) based on your maintenance preferences and application demands.

Select Phase Configuration: Opt for 3-phase or 4-phase configurations depending on your electrical setup.

PVC Sleeves: Red Yellow Blue Sleeves for 3 phase and Red Yellow Blue Green PVC Sleeves for 3 Phase + neutral .

By considering these factors and referring to our recommended busbars, you can confidently make an informed decision for your specific electrical needs. If you require further

assistance, our team is always ready to help you choose the right busbar for your application.

What are DSL Busbars?

Shrouded DSL Busbars are made up of highly electrically conductive sheet metal and they distribute and carry power

from source to a destination or multiple destinations. They can be used in all kinds of Factories,

Buildings, Malls, Airports etc.

DSL Busbars come in a variety of configurations, shapes, sizes, materials and current carrying capacity.

When you need to conduct a significant amount of current, DSL busbars are your best bet.

For example, if you want to power many of your heavy duty cranes in one bay, you use a system of DSL busbars.

The efficiency of a busbar will depend upon the Ratio of the Input Power to the Power Output.

In Low Power Systems Such as a ‘pcb’ in a household or industrial appliance,the ground or Power plane can be thought of as a bus bar.Current in these low power systems tend to be in the milli ampere range.

In High Power Systems, where you have to transfer 1000 Amperes of Current through a three phase busbar system, it is a different game. The design, Installation, Safety during such an installation become critical factors.

What is the Need for DSL Busbars?

They are a very efficient system to carry significant amounts of current between different electrical subsystems.

Where are DSL Busbars used?

-

Factories

-

Buildings

-

Airports

A busbar is not the only solution to deliver power to your machinery but it can be used in many different configurations.

What is the Current carrying capacity of DSL Busbars?

The Current carrying capacity of the busbar are highly dependent on the operating temperature. In an Industrial environment, most of the heat lost by the busbar will be due to Convection. Current carrying capacity of a busbar can range from 1 Ampere to 1200 Amperes.

-

40 Ampere DSL Busbar

-

60 Ampere DSL Busbar

-

100 Ampere DSL Busbar

-

140 Ampere DSL Busbar

-

200 Ampere DSL Busbar

-

250 Ampere DSL Busbar

-

300 Ampere DSL Busbar

-

400 Ampere DSL Busbar

-

500 Ampere DSL Busbar

-

600 Ampere DSL Busbar

-

700 Ampere DSL Busbar

-

800 Ampere DSL Busbar

-

900 Ampere DSL Busbar

-

1000 Ampere DSL Busbar

-

1200 Ampere DSL Busbar

Does the Resistance of a Busbar Matter?

Yes, it matters.

Heat generated by the busbar = I2R

Where I = Current Carried By the Busbar

R = Resistance of the busbar

Increase in resistance of the dsl busbar, produces more heat which in turn reduces the total power efficiency of the dsl busbar system decreases.

Which DSL Busbar Should I choose for my application?

- – Energy Efficiency Required

- – Current Carrying Capacity Required

- – Life Time Cost

- – Length of DSL Busbar Installation

- – Maintenance Procedures of Different DSL Busbars

- – Cooling Method Provided to the DSL Busbar

- – Inductance & Capacitance of Longer DSL Busbars

- – Space Constraints

- – Cost Constraints

Materials Used in DSL Busbars

DSL Busbars are typically made of high-conductivity materials, such as GI ,copper and aluminum, that are able to transmit electrical power effectively with minimal loss. The choice of material depends on the specific requirements of the application and the operating conditions of the EOT crane.

Copper is a popular choice for DSL Busbars due to its excellent electrical conductivity, durability, and resistance to corrosion. It is also a flexible material, making it ideal for customizing the busbars to fit the specific requirements of different EOT cranes. However, copper is also a relatively expensive material, making it a less economical choice for some applications.

Aluminum is another common material used for DSL Busbars. It has lower conductivity compared to copper but is lighter and more economical. Aluminum is also resistant to corrosion and can last for many years with minimal maintenance, making it a reliable choice for industrial applications.

Upto 125 Amps GI DSL Busbar is the most economical choice.

When there is highly corrosive environment Stainless Steel DSL Busbars are used if Amperes required in low.

In some cases, other high-conductivity materials, such as silver, may be used for DSL Busbars. However, these materials are typically more expensive and are only used in specialized applications where their high conductivity is critical.

In addition to the conductive material, the busbars are usually supported by insulating material, such as ceramic or fiberglass, to prevent electrical accidents and ensure the safety of workers. These materials are chosen for their high resistance to electrical and thermal stress, as well as their ability to withstand the harsh conditions of industrial environments.

SS DSL Busbar

Used in corrosive atmosphere, chemical plants, 60 Amps in W type.

Galvanized Iron DSL Busbar

Let's go through the important technical parameters of Iron as a metal:

Melting point of Iron: 1538 °C

Boiling Point of Iron: 2862 °C

Density of Iron: 7.874 g/cm 3

Electrical Resistivity of Iron: 96.1 nΩm

Applications of Iron DSL Busbars are in trolleys, over head cranes, hoists.

Aluminium DSL Busbar

Let's go through the important technical parameters of Aluminium as a metal:

Melting point of Aluminium: 660.32 °C

Boiling Point of Aluminium: 2470 °C

Density of Aluminium: 2.7 g/cm 3

Electrical Resistivity of Aluminium: 26.5 nΩm

Properties of Aluminium:

Aluminium is ready available because it makes up almost 10 percent of the earths’ crust. Aluminium has

almost 33% density of copper or Steel. When exposed to air, aluminiums’ outer layer oxidizes and helps in

making aluminium excellent at corrosion resistance and hence aluminium maintains a good silvery finish at

all times.

Aluminium is a good material for DSL Busbars because of its very High electrical and thermal conductivity,

low Density, excellent corrosion resistance and high mechanical strength.

Aluminium DSL Busbars are cheaper than copper DSL Busbars but offer about 60 % of coppers electrical conductivity.

Aluminium also weighs almost half of copper DSL Busbars. Since Aluminium is a soft metal, Aluminium DSL Busbars

can be made with the help of rolling machines or extrusion machines.

Copper DSL Busbar

First lets go through the important technical parameters of Copper as a metal:

Melting point of Copper: 1082 Degrees

Boiling Point of Copper: 2564 Degrees

Density of Copper: 8.96 g/cm 3

Electrical Resistivity of Copper: 16.78 nΩMeter

Since Copper is malleable and Ductile it can be formed into many different kinds of shapes. It also has a

high thermal conductivity to spread out the heat evenly. Due to all these parameters, copper is the most

favoured material to be used in DSL Busbars.

Copper DSL Busbars are much superior to aluminium DSL Busbars in terms of conductivity but the trade off here is

cost and weight. Since the density of copper is high, it is more robust to external mechanical disturbances

and damage.

Copper DSL Busbars will transfer significant amounts of current, hence, there will be a small percentage of

power lost in transmission and converted into heat. This heat will be lost to the external environment

through convection and radiation.

Product List of DSL Busbars.

| Sr. no. | Product Name | Description | Part Number | Images |

|---|---|---|---|---|

| 1 | SafelinkM 125Amp GI RYB | 125 Amp - GI - 03 BAR PIN TYPE RED YELLOW BLUE COLOUR PVC | SLM-125-RYB-GI | |

| 2 | SafelinkM 160Amp CU RYB | 160 Amp - Copper - 03 BAR PIN TYPE RED YELLOW BLUE COLOUR PVC | SLM-160-RYB-CU | |

| 3 | SafelinkM 250Amp CU RYB | 250 Amp - Copper - 03 BAR PIN TYPE RED YELLOW BLUE COLOUR PVC | SLM-250-RYB-CU | |

| 4 | SafelinkM 315Amp CU RYB | 315 Amp - Copper - 03 BAR PIN TYPE RED YELLOW BLUE COLOUR PVC | SLM-315-RYB-CU | |

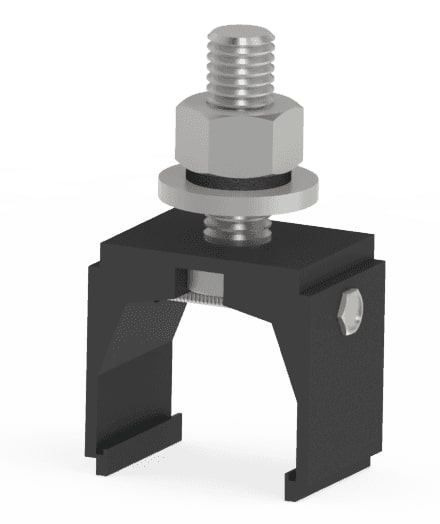

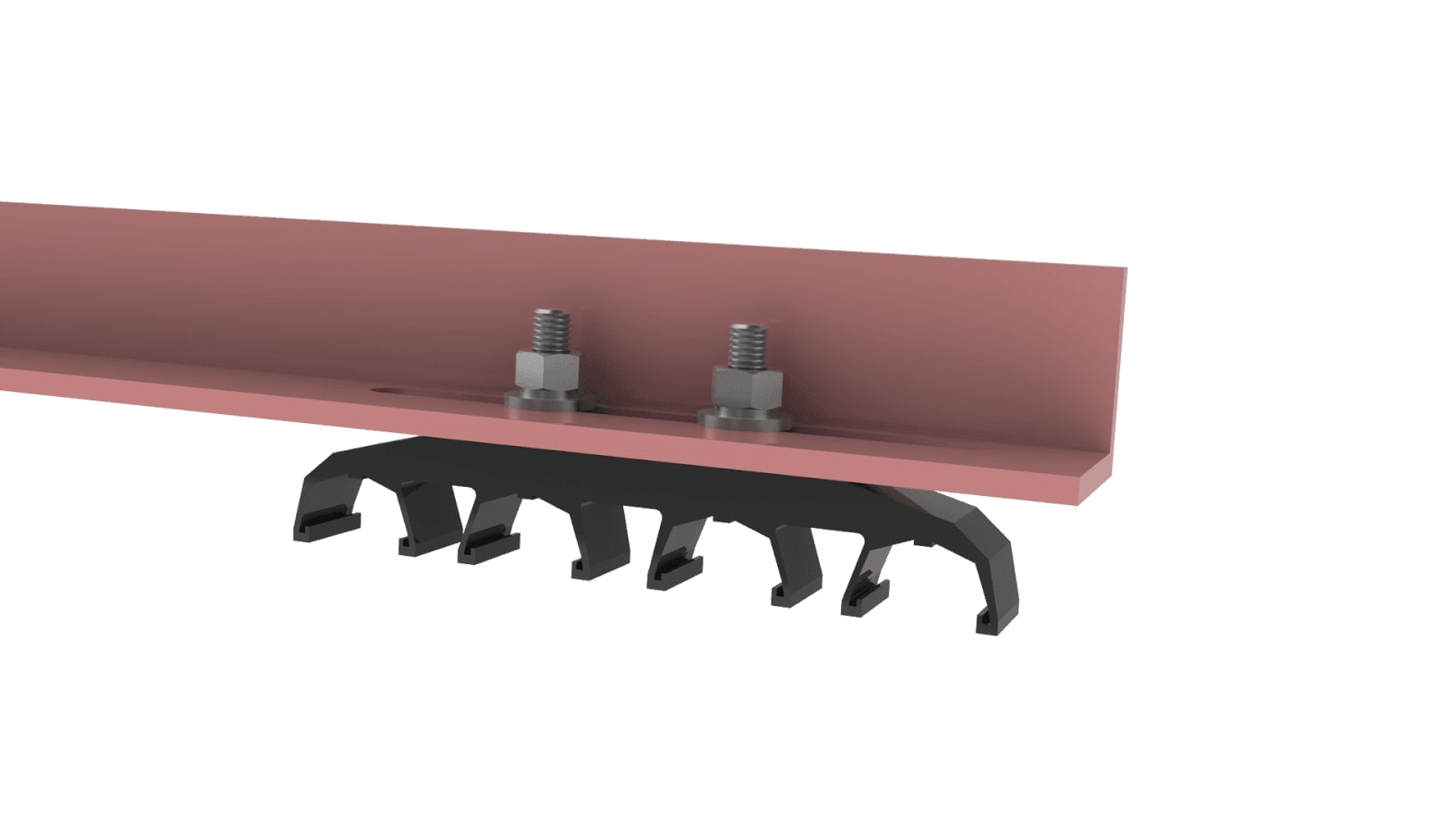

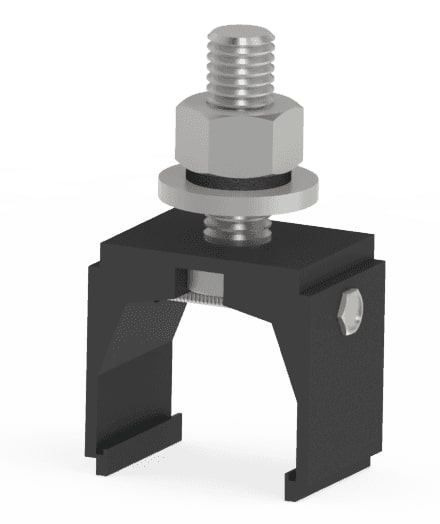

| 5 | SafelinkM 1Pole Hangar Clamp | 01 POLE HANGER CLAMP | SLM-1PH | |

| 6 | SafelinkM 4Pole Hangar Clamp | 04 POLE HANGER CLAMP | SLM-4PH | |

| 7 | SafelinkM 1Pole Anchor Clamp | 01 POLE ANCHOR CLAMP | SLM-1PAC | |

| 8 | SafelinkM JointCover | JOINT COVER / SPLICE COVER | SLM-JC | |

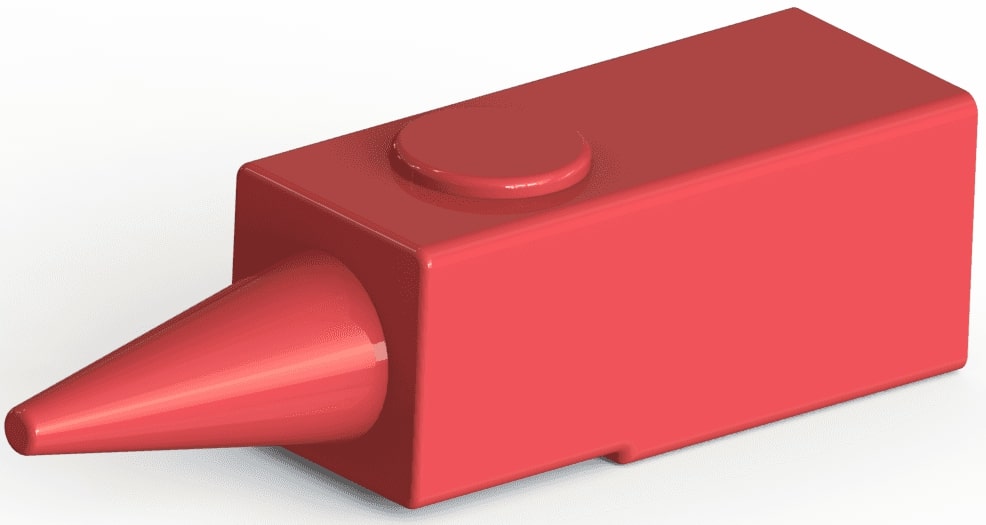

| 9 | SafelinkM Endcap | END CAP | SLM-EC | |

| 10 | SafelinkM End Power Feed | END POWER FEED WITH COVER | SLM-EPF |

|

| 11 | SafelinkM Center Power Feed | CENTER POWRE FEED | SLM-CPF | |

| 12 | SafelinkM Jointing Tool | JOINTING TOOLS | SLM-JT | |

| 13 | SafelinkM Red Sleeve | RED PVC SLEEVES 4 MTR LONG M TYPE | SLM-R-SLEEVE | |

| 14 | SafelinkM Yellow Sleeve | YELLOW PVC SLEEVES 4 MTR LONG M TYPE | SLM-Y-SLEEVE | |

| 15 | SafelinkM Blue Sleeve | BLUE PVC SLEEVES 4 MTR LONG M TYPE | SLM-B-SLEEVE | |

| 16 | SafelinkM Green Sleeve | GREEN PVC SLEEVES 4 MTR LONG M TYPE | SLM-G-SLEEVE |

|

| 17 | SafelinkW 60Amp GI RYBG | 60 Amp - GI - 04 BAR BOLTED (W) TYPE RED YELLOW BLUE GREEN COLOUR PVC | SLW-60-RYBG-GI | |

| 18 | SafelinkW 100Amp GI RYBG | 100 Amp - GI - 04 BAR BOLTED (W) TYPE RED YELLOW BLUE GREEN COLOUR PVC | SLW-100-RYBG-GI | |

| 19 | SafelinkW 125Amp GI RYBG | 125 Amp - GI - 04 BARBOLTED (W) TYPE RED YELLOW BLUE GREEN COLOUR PVC | SLW-125-RYBG-GI | |

| 20 | SafelinkW 160Amp CU RYBG | 160 Amp - Copper - 04 BAR BOLTED (W) TYPE RED YELLOW BLUE GREEN COLOUR PVC | SLW-160-RYBG-CU | |

| 21 | SafelinkW 160Amp CU-GI RYBG | 160 Amp - Copper - 04 BAR BOLTED (W) TYPE RED YELLOW BLUE GREEN COLOUR PVC, 3 Copper Busbars and 1 GI Busbar. | SLW-160-RYB-CU,G-GI | |

| 22 | SafelinkW 200Amp ALU RYBG | 200 Amp - Aluminium - 04 BAR BOLTED (W) TYPE RED YELLOW BLUE GREEN COLOUR PVC | SLW-200-RYBG-ALU | |

| 23 | SafelinkW 250Amp CU RYBG | 250 Amp - Copper - 04 BAR BOLTED (W) TYPE RED YELLOW BLUE GREEN COLOUR PVC | SLW-250-RYBG-CU | |

| 24 | SafelinkW 250Amp CU-GI RYBG | 250 Amp - Copper - 04 BAR BOLTED (W) TYPE RED YELLOW BLUE GREEN COLOUR PVC, 3 Copper Busbars and 1 GI Busbar. | SLW-250-RYB-CU,G-GI | |

| 25 | SafelinkW 315Amp ALU RYBG | 315 Amp - Aluminium - 04 BAR BOLTED (W) TYPE RED YELLOW BLUE GREEN COLOUR PVC | SLW-315-RYBG-ALU | |

| 26 | SafelinkW 400Amp CU-GI RYBG | 400 Amp - Copper - 04 BAR BOLTED (W)TYPE RED YELLOW BLUE GREEN COLOUR PVC, 3 Copper Busbars and 1 GI Busbar. | SLW-400-RYB-CU,G-GI | |

| 27 | SafelinkW 400Amp ALU RYBG | 400 Amp - Aluminium - 04 BAR BOLTED (W) TYPE RED YELLOW BLUE GREEN COLOUR PVC | SLW-400-RYBG-ALU | |

| 28 | SafelinkW 60Amp GI RYB | 60 Amp - GI - 03 BAR BOLTED (W) TYPE RED YELLOW BLUE COLOUR PVC | SLW-60-RYB-GI | |

| 29 | SafelinkW 100Amp GI RYB | 100 Amp - GI - 03 BAR BOLTED (W) TYPE RED YELLOW BLUE COLOUR PVC | SLW-100-RYB-GI | |

| 30 | SafelinkW 125Amp GI RYB | 125 Amp - GI - 03 BAR BOLTED (W) TYPE RED YELLOW BLUE COLOUR PVC | SLW-125-RYB-GI | |

| 31 | SafelinkW 160Amp CU RYB | 160 Amp - Copper - 03 BAR BOLTED (W) TYPE RED YELLOW BLUE COLOUR PVC | SLW-160-RYB-CU | |

| 32 | SafelinkW 200Amp ALU RYB | 160 Amp - Aluminium - 03 BAR BOLTED (W) TYPE RED YELLOW BLUE COLOUR PVC | SLW-200-RYB-ALU | |

| 33 | SafelinkW 250Amp CU RYB | 250 Amp - Copper - 03 BAR BOLTED (W) TYPE RED YELLOW BLUE COLOUR PVC | SLW-250-RYB-CU | |

| 34 | SafelinkW 315Amp ALU RYB | 315 Amp - Aluminium - 03 BAR BOLTED (W) TYPE RED YELLOW BLUE COLOUR PVC | SLW-315-RYB-ALU | |

| 35 | SafelinkW 400Amp ALU RYB | 400 Amp - Aluminium - 03 BAR BOLTED (W) TYPE RED YELLOW BLUE COLOUR PVC | SLW-400-RYB-ALU | |

| 36 | SafelinkW 60Amp GI RYBG Expansion Assembly | Expansion Assembly 60 Amp - GI - 04 BAR BOLTED (W) TYPE | SLW-60-RYBG-GI-Expansion-Assembly | |

| 37 | SafelinkW 160Amp CU RYBG Expansion Assembly | Expansion Assembly 160 Amp - Copper - 04 BAR BOLTED (W) TYPE | SLW-160-RYBG-CU-Expansion-Assembly | |

| 38 | SafelinkW 160Amp CU-GI RYBG Expansion Assembly | Expansion Assembly 160 Amp - Copper - 04 BAR BOLTED (W) TYPE | SLW-160-RYB-CU,G-GI-Expansion-Assembly | |

| 39 | SafelinkW 250Amp CU RYBG Expansion Assembly | Expansion Assembly 250 Amp - Copper - 04 BAR BOLTED (W) TYPE | SLW-250-RYBG-CU-Expansion-Assembly | |

| 40 | SafelinkW 250Amp CU-GI RYBG Expansion Assembly | Expansion Assembly 250 Amp - Copper - 04 BAR BOLTED (W) TYPE | SLW-250-RYB-CU,G-GI-Expansion-Assembly | |

| 41 | SafelinkW 400Amp CU RYBG Expansion Assembly | Expansion Assembly 400 Amp - Copper - 04 BAR BOLTED (W) TYPE | SLW-400-RYBG-CU-Expansion-Assembly | |

| 42 | SafelinkW 400Amp CU-GI RYBG Expansion Assembly | Expansion Assembly 400 Amp - Copper - 04 BAR BOLTED (W)TYPE | SLW-400-RYB-CU,G-GI-Expansion-Assembly | |

| 43 | SafelinkW 400Amp ALU RYBG Expansion Assembly | Expansion Assembly 400 Amp - Aluminium - 04 BAR BOLTED (W) TYPE | SLW-400-RYBG-ALU-Expansion-Assembly | |

| 44 | SafelinkW 60Amp GI RYB Expansion Assembly | Expansion Assembly 60 Amp - GI - 03 BAR BOLTED (W) TYPE | SLW-60-RYB-GI-Expansion-Assembly | |

| 45 | SafelinkW 100Amp GI RYB Expansion Assembly | Expansion Assembly 100 Amp - GI - 03 BAR BOLTED (W) TYPE | SLW-100-RYB-GI-Expansion-Assembly | |

| 46 | SafelinkW 125Amp GI RYB Expansion Assembly | Expansion Assembly 125 Amp - GI - 03 BAR BOLTED (W) TYPE | SLW-125-RYB-GI-Expansion-Assembly | |

| 47 | SafelinkW 160Amp CU RYB Expansion Assembly | Expansion Assembly 160 Amp - Copper - 03 BAR BOLTED (W) TYPE | SLW-160-RYB-CU-Expansion-Assembly | |

| 48 | SafelinkW 200Amp ALU RYB Expansion Assembly | Expansion Assembly 160 Amp - Aluminium - 03 BAR BOLTED (W) TYPE | SLW-200-RYB-ALU-Expansion-Assembly | |

| 49 | SafelinkW 250Amp CU RYB Expansion Assembly | Expansion Assembly 250 Amp - Copper - 03 BAR BOLTED (W) TYPE | SLW-250-RYB-CU-Expansion-Assembly | |

| 50 | SafelinkW 315Amp ALU RYB Expansion Assembly | Expansion Assembly 315 Amp - Aluminium - 03 BAR BOLTED (W) TYPE | SLW-315-RYB-ALU-Expansion-Assembly | |

| 51 | SafelinkW 400Amp CU RYB Expansion Assembly | Expansion Assembly 400 Amp - Copper - 03 BAR BOLTED (W) TYPE | SLW-400-RYB-CU-Expansion-Assembly | |

| 52 | SafelinkW 400Amp ALU RYB Expansion Assembly | Expansion Assembly 400 Amp - Aluminium - 03 BAR BOLTED (W) TYPE | SLW-400-RYB-ALU-Expansion-Assembly | |

| 53 | SafelinkW 1Pole Hangar Clamp | 01 POLE HANGER CLAMP | SLW-1PH | |

| 54 | SafelinkW 3Pole Hangar Clamp | 03 POLE HANGER CLAMP | SLW-3PH | |

| 55 | SafelinkW 4Pole Hangar Clamp | 04 POLE HANGER CLAMP | SLW-4PH | |

| 56 | SafelinkW 1Pole Anchor Clamp | 01 POLE ANCHOR CLAMP | SLW-1PA | |

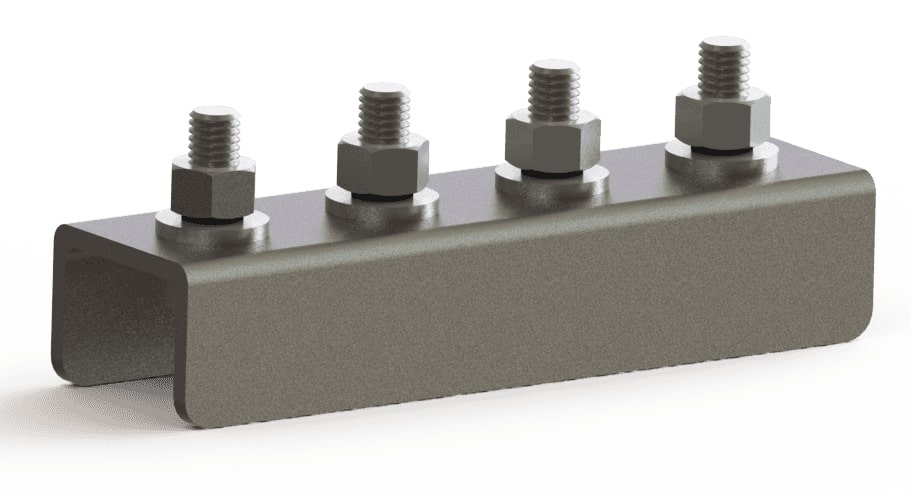

| 57 | SafelinkW GI Joint | G.I. JOINT | SLW-JGI | |

| 58 | SafelinkW CU Joint | COPPER JOINT | SLW-JCU |

|

| 59 | SafelinkW ALU Joint | ALUMINUM JOINT | SLW-JAL | |

| 60 | SafelinkW GI Center Power Feed | CENTER POWER FEED GI | SLW-CPF-GI |

|

| 61 | SafelinkW CU CenterPowerFeed | CENTER POWER FEED CU | SLW-CPF-CU |

|

| 62 | SafelinkW ALU CenterPowerFeed | CENTER POWER FEED AL | SLW-CPF-AL |

|

| 63 | SafelinkW End Cap | END CAP | SLW-EC |

|

| 64 | SafelinkW End Power Feed | END POWER FEED | SLW-EPF | |

| 65 | SafelinkW Joint Cover | JOINT COVER | SLW-JC |

|

| 66 | SafelinkW Transfer Cap | TRANSFER CAP | SLW-TC | |

| 67 | SafelinkW Red Sleeve | PVC SLEEVE 4.5MTR LONG (R) | SLW-R-SLEEVE | |

| 68 | SafelinkW Yellow Sleeve | PVC SLEEVE 4.5MTR LONG (Y) | SLW-Y-SLEEVE | |

| 69 | SafelinkW Blue Sleeve | PVC SLEEVE 4.5MTR LONG (B) | SLW-B-SLEEVE |

|

| 70 | SafelinkW Green Sleeve | PVC SLEEVE 4.5MTR LONG (G) | SLW-G-SLEEVE | |

| 71 | SafelinkV 500A ALU YYYG | 500AMP ALUMINIUM 04 BAR V TYPE YELLOW,YELLOW,YELLOW, GREEN COLOUR PVC | SLV-500-YYYG-AL | |

| 72 | SafelinkV 800A ALU YYYG | 800AMP ALUMINIUM 04 BAR V TYPE YELLOW,YELLOW,YELLOW, GREEN COLOUR PVC | SLV-800-YYYG-AL |

|

| 73 | SafelinkV 1000A ALU YYYG | 1000AMP ALUMINIUM 04 BAR V TYPE YELLOW,YELLOW,YELLOW, GREEN COLOUR PVC | SLV-1000-YYYG-AL |

|

| 74 | SafelinkV 1250A ALU YYYG | 1250AMP ALUMINIUM 04 BAR V TYPE YELLOW,YELLOW,YELLOW, GREEN COLOUR PVC | SLV-1250-YYYG-AL |

|

| 75 | SafelinkV 500A CU YYYG | 500AMP COPPER 04 BAR V TYPE YELLOW,YELLOW,YELLOW, GREEN COLOUR PVC | SLV-500-YYYG-CU |

|

| 76 | SafelinkV 800A CU YYYG | 800AMP COPPER 04 BAR V TYPE YELLOW,YELLOW,YELLOW, GREEN COLOUR PVC | SLV-800-YYYG-CU |

|

| 77 | SafelinkV 1000A CU YYYG | 1000AMP COPPER 04 BAR V TYPE YELLOW,YELLOW,YELLOW, GREEN COLOUR PVC | SLV-1000-YYYG-CU | |

| 78 | SafelinkV 1250A CU YYYG | 1250AMP COPPER 04 BAR V TYPE YELLOW,YELLOW,YELLOW, GREEN COLOUR PVC | SLV-1250-YYYG-CU | |

| 79 | SafelinkV 500A ALU YYY | 500AMP ALUMINIUM 03 BAR V TYPE YELLOW,YELLOW,YELLOW COLOUR PVC | SLV-500-YYY-AL | |

| 80 | SafelinkV 800A ALU YYY | 800AMP ALUMINIUM 03 BAR V TYPE YELLOW,YELLOW,YELLOW COLOUR PVC | SLV-800-YYY-AL | |

| 81 | SafelinkV 1000A ALU YYY | 1000AMP ALUMINIUM 03 BAR V TYPE YELLOW,YELLOW,YELLOW COLOUR PVC | SLV-1000-YYY-AL | |

| 82 | SafelinkV 1250A ALU YYY | 1250AMP ALUMINIUM 03 BAR V TYPE YELLOW,YELLOW,YELLOW COLOUR PVC | SLV-1250-YYY-AL | |

| 83 | SafelinkV 500A CU YYY | 500AMP COPPER 03 BAR V TYPE YELLOW,YELLOW,YELLOW COLOUR PVC | SLV-500-YYY-CU | |

| 84 | SafelinkV 800A CU YYY | 800AMP COPPER 03 BAR V TYPE YELLOW,YELLOW,YELLOW COLOUR PVC | SLV-800-YYY-CU | |

| 85 | SafelinkV 1000A CU YYY | 1000AMP COPPER 03 BAR V TYPE YELLOW,YELLOW,YELLOW COLOUR PVC | SLV-1000-YYY-CU | |

| 86 | SafelinkV 1250A CU YYY | 1250AMP COPPER 03 BAR V TYPE YELLOW,YELLOW,YELLOW COLOUR PVC | SLV-1250-YYY-CU | |

| 87 | SafelinkV 500A ALU YYYG Expansion Assembly | Expansion Assembly 500AMP ALUMINIUM 04 BAR V TYPE | SLV-500-YYYG-AL-Expansion | |

| 88 | SafelinkV 800A ALU RYBG Expansion Assembly | Expansion Assembly 800AMP ALUMINIUM 04 BAR V TYPE | SLV-800-YYYG-AL-Expansion | |

| 89 | SafelinkV 1000A ALU RYBG Expansion Assembly | Expansion Assembly 1000AMP ALUMINIUM 04 BAR V TYPE | SLV-1000-YYYG-AL-Expansion | |

| 90 | SafelinkV 1250A ALU RYBG Expansion Assembly | Expansion Assembly 1250AMP ALUMINIUM 04 BAR V TYPE | SLV-1250-YYYG-AL-Expansion | |

| 91 | SafelinkV 500A CU RYBG Expansion Assembly | Expansion Assembly 500AMP COPPER 04 BAR V TYPE | SLV-500-YYYG-CU-Expansion | |

| 92 | SafelinkV 800A CU RYBG Expansion Assembly | Expansion Assembly 800AMP COPPER 04 BAR V TYPE | SLV-800-YYYG-CU-Expansion | |

| 93 | SafelinkV 1000A CU RYBG Expansion Assembly | Expansion Assembly 1000AMP COPPER 04 BAR V TYPE | SLV-1000-YYYG-CU-Expansion | |

| 94 | SafelinkV 1250A CU RYBG Expansion Assembly | Expansion Assembly 1250AMP COPPER 04 BAR V TYPE | SLV-1250-YYYG-CU-Expansion | |

| 95 | SafelinkV 500A ALU RYB Expansion Assembly | Expansion Assembly 500AMP ALUMINIUM 03 BAR V TYPE | SLV-500-AL-Expansion | |

| 96 | SafelinkV 800A ALU RYB Expansion Assembly | Expansion Assembly 800AMP ALUMINIUM 03 BAR V TYPE | SLV-800-AL-Expansion | |

| 97 | SafelinkV 1000A ALU RYB Expansion Assembly | Expansion Assembly 1000AMP ALUMINIUM 03 BAR V TYPE | SLV-1000-AL-Expansion | |

| 98 | SafelinkV 1250A ALU RYB Expansion Assembly | Expansion Assembly 1250AMP ALUMINIUM 03 BAR V TYPE | SLV-1250-AL-Expansion | |

| 99 | SafelinkV 500A CU RYB Expansion Assembly | Expansion Assembly 500AMP COPPER 03 BAR V TYPE | SLV-500-CU-Expansion | |

| 100 | SafelinkV 800A CU RYB Expansion Assembly | Expansion Assembly 800AMP COPPER 03 BAR V TYPE | SLV-800-CU-Expansion | |

| 101 | SafelinkV 1000A CU RYB Expansion Assembly | Expansion Assembly 1000AMP COPPER 03 BAR V TYPE | SLV-1000-CU-Expansion | |

| 102 | SafelinkV 1250A CU RYB Expansion Assembly | Expansion Assembly 1250AMP COPPER 03 BAR V TYPE | SLV-1250-CU-Expansion | |

| 103 | SafelinkV 1Pole Hangar Clamp | SINGLE POLE HANGER CLAMP | SL-V-1PH | |

| 104 | SafelinkV 1Pole Anchor Clamp | ANCHOR CLAMP | SL-V-AC | |

| 105 | SafelinkV ALU Joint | BOLTED JOINT - ALUMINIUM | SL-V-BJ-A | |

| 106 | SafelinkV CU Joint | BOLTED JOINT - COPPER | SL-V-BJ-C | |

| 107 | SafelinkV JointCover | JOINT COVER | SL-V-JC | |

| 108 | SafelinkV ALU Center Power Feed | CENTER POWER FEED AL | SL-V-CPF-A |

|

| 109 | SafelinkV CU Center Power Feed | CENTER POWER FEED CU | SL-V-CPF-C |

|

| 110 | SafelinkV EndCover | END COVER/TRANSFER FUNNEL | SL-V-EC |

|

| 111 | SafelinkV Sleeve | Sleeve | SLV-PVC | |

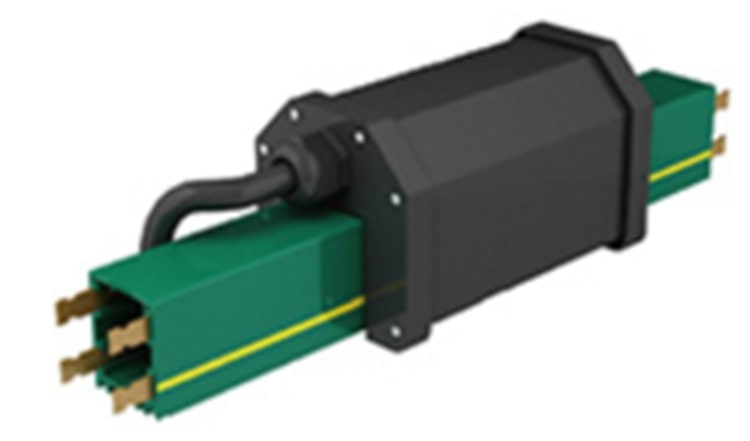

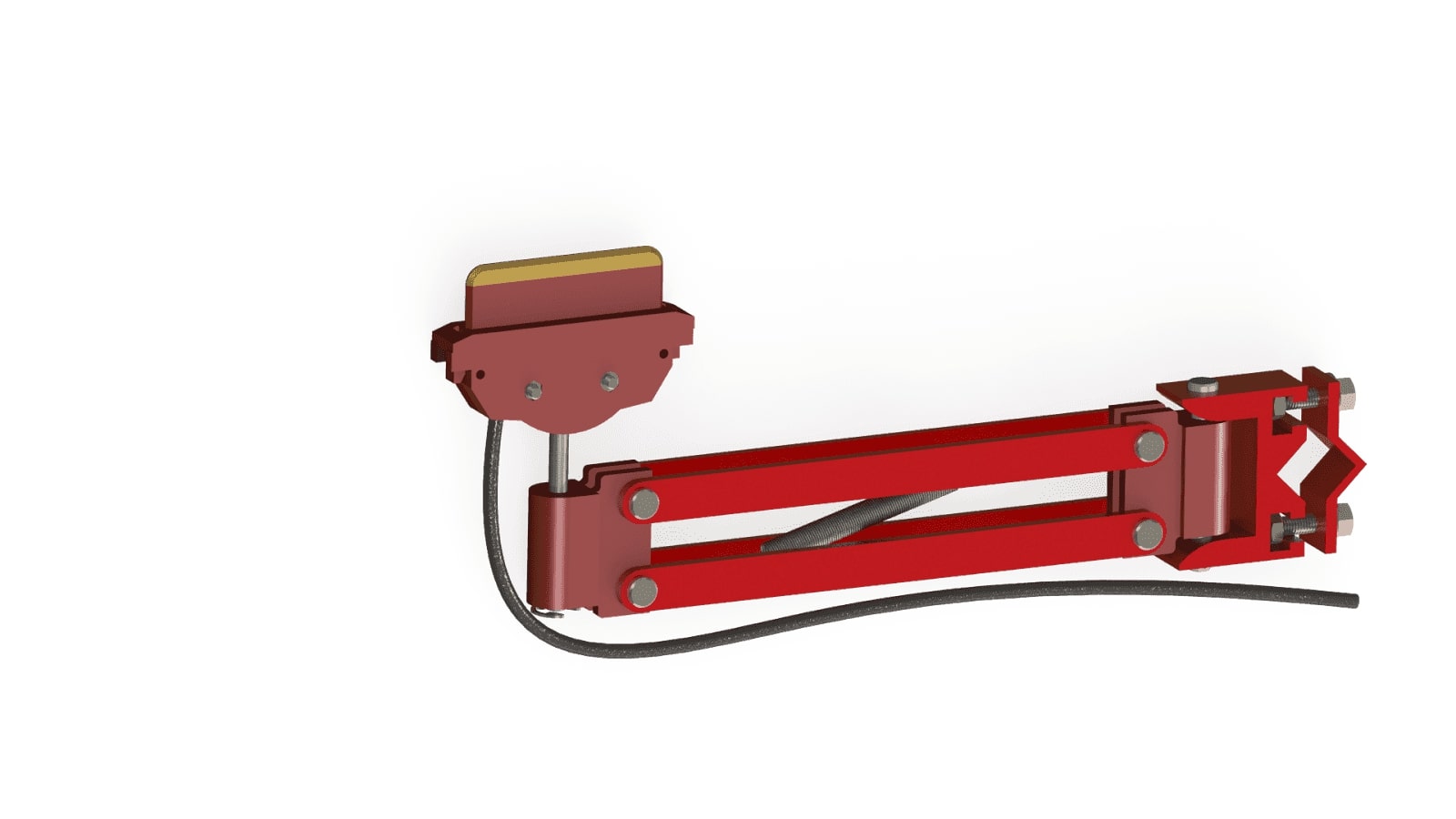

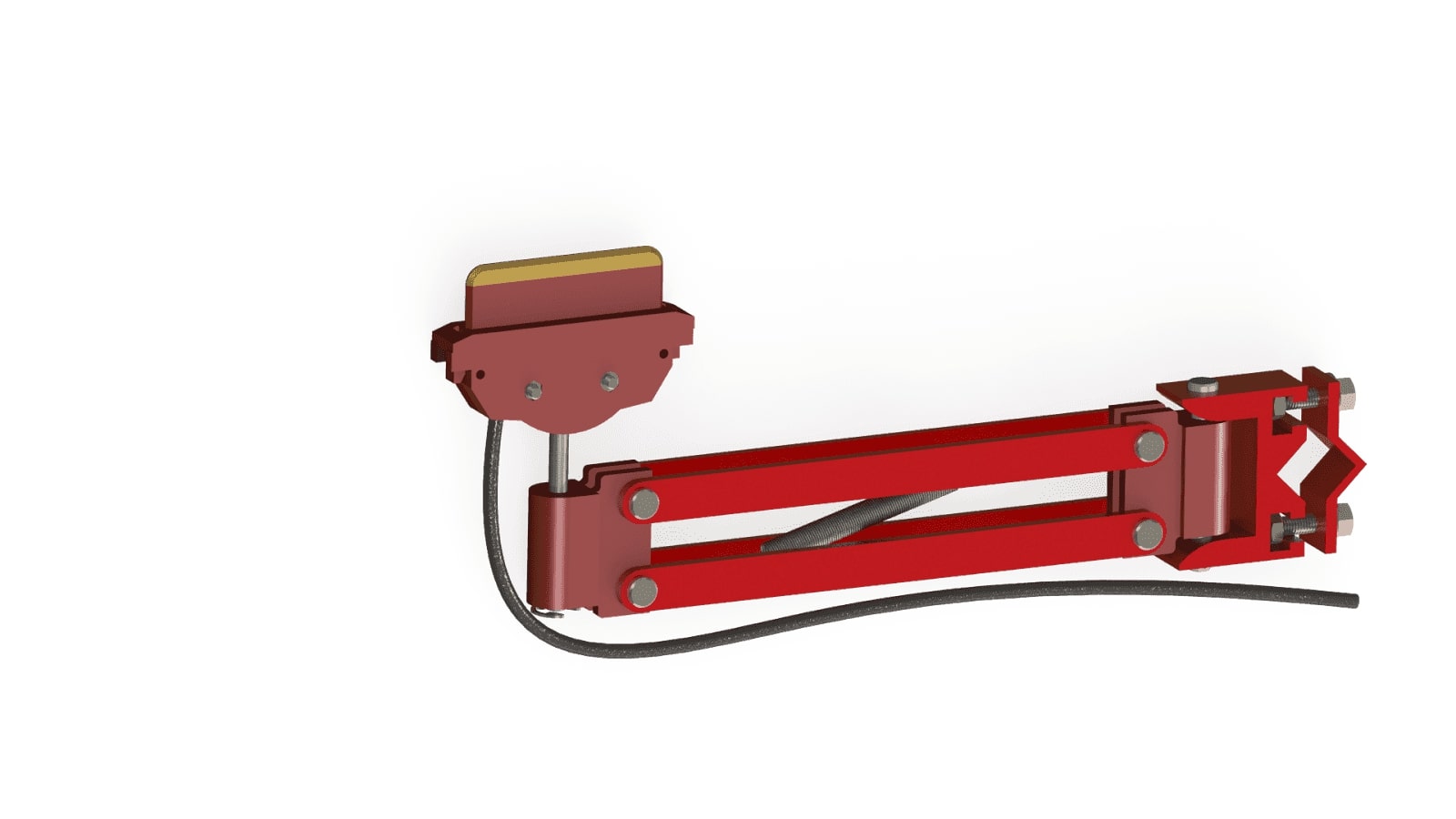

| 112 | CURRENT COLLECTOR 100AMP 1 Meter Cable | CURRENT COLLECTOR 100AMP - 1 Meter Cable | SLCC100A-1M | |

| 113 | CURRENT COLLECTOR 125AMP 1 Meter Cable | CURRENT COLLECTOR 125AMP - 1 Meter Cable | SLCC125A-1M | |

| 114 | CURRENT COLLECTOR 100AMP 1.5 Meter Cable | CURRENT COLLECTOR 100AMP - 1.5 Meter Cable | SLCC100A-1.5M | |

| 115 | CURRENT COLLECTOR 125AMP 1.5 Meter Cable | CURRENT COLLECTOR 125AMP - 1.5 Meter Cable | SLCC125A-1.5M | |

| 116 | CURRENT COLLECTOR 125AMP 3 Meter Cable | CURRENT COLLECTOR 125AMP - 3 Meter Cable | SLCC125A-3M | |

| 117 | CURRENT COLLECTOR 125AMP 5 Meter Cable | CURRENT COLLECTOR 125AMP - 5 Meter Cable | SLCC125A-5M |

|

| 118 | CURRENT COLLECTOR 125AMP x 2 - 1.5 Meter Cable | CURRENT COLLECTOR 125AMP x 2 - 1.5 Meter Cable | SLCC125Ax2-1.5m |

|

| 119 | CURRENT COLLECTOR 250AMP - 1.5 Meter Cable | CURRENT COLLECTOR 250AMP - 1.5 Meter Cable | SLCC250A-1.5M |

|

| 120 | CURRENT COLLECTOR 250AMP - 3 Meter Cable | CURRENT COLLECTOR 250AMP - 3 Meter Cable | SLCC250A-3M | |

| 121 | CURRENT COLLECTOR 250AMP - 5 Meter Cable | CURRENT COLLECTOR 250AMP - 5 Meter Cable | SLCC250A-5M |

|

| 122 | CURRENT COLLECTOR 250AMP x 2 - 1.5 Meter | CURRENT COLLECTOR 250AMP x 2 - 1.5 Meter | SLCC250Ax2-1.5M | |

| 123 | CURRENT COLLECTOR 500AMP - 1.5 Meter | CURRENT COLLECTOR 500AMP - 1.5 Meter | SLCC500A | |

| 124 | CURRENT COLLECTOR 500AMP - 5 Meter | CURRENT COLLECTOR 500AMP - 5 Meter | SLCC500A-5M | |

| 125 | CURRENT COLLECTOR 500AMP x 2 - 1.5 Meter | CURRENT COLLECTOR 500AMP x 2 - 1.5 Meter | SLCC500Ax2 | |

| 126 | CURRENT COLLECTOR SHOE - 125 Amps | CURRENT COLLECTOR SHOE - 125 Amps | SLCC-125-S | |

| 127 | CURRENT COLLECTOR SHOE WITH HOLDER - 125 Amps | CURRENT COLLECTOR SHOE WITH HOLDER - 125 Amps | SLCC-125-SH | |

| 128 | CURRENT COLLECTOR SHOE - 250 Amps | CURRENT COLLECTOR SHOE - 250 Amps | SLCC-250-S | |

| 129 | CURRENT COLLECTOR SHOE WITH HOLDER - 250 Amps | CURRENT COLLECTOR SHOE WITH HOLDER - 250 Amps | SLCC-250-SH |

|

| 130 | CURRENT COLLECTOR SHOE - 500 Amps | CURRENT COLLECTOR SHOE - 500 Amps | SLCC-500-S | |

| 131 | CURRENT COLLECTOR SHOE WITH HOLDER - 500 Amps | CURRENT COLLECTOR SHOE WITH HOLDER - 500 Amps | SLCC-500-SH |

|

| 132 | CURRENT COLLECTOR SINGLE BRACKET | CURRENT COLLECTOR SINGLE BRACKET | SLCC-B |

|

| 133 | CURRENT COLLECTOR DOUBLE BRACKET | CURRENT COLLECTOR DOUBLE BRACKET | SLCC-DB |

|

| 134 | WEB BRACKET 400MM LONG | WEB BRACKET 400MM LONG | SL-WB-400 |

|

| 135 | WEB BRACKET 450MM LONG | WEB BRACKET 450MM LONG | SL-WB-450 |

|

| 136 | WEB BRACKET 600MM LONG | WEB BRACKET 600MM LONG | SL-WB-600 | |

| 137 | WEB BRACKET 650MM LONG | WEB BRACKET 650MM LONG | SL-WB-650 | |

| 138 | 40AMP ENCLOSED TYPE 04 POLE COPPER JOINT TYPE | 40AMP ENCLOSED TYPE 04 POLE COPPER JOINT TYPE | SLE-40 | |

| 139 | 60AMP ENCLOSED TYPE 04 POLE COPPER JOINT TYPE | 60AMP ENCLOSED TYPE 04 POLE COPPER JOINT TYPE | SLE-60 | |

| 140 | 80AMP ENCLOSED TYPE 04 POLE COPPER JOINT TYPE | 80AMP ENCLOSED TYPE 04 POLE COPPER JOINT TYPE | SLE-80 | |

| 141 | 100AMP ENCLOSED TYPE 04 POLE COPPER JOINT TYPE | 100AMP ENCLOSED TYPE 04 POLE COPPER JOINT TYPE | SLE-100 | |

| 142 | 140AMP ENCLOSED TYPE 04 POLE COPPER JOINT TYPE | 140AMP ENCLOSED TYPE 04 POLE COPPER JOINT TYPE | SLE-140 | |

| 143 | 200AMP ENCLOSED TYPE 04 POLE COPPER JOINT TYPE | 200AMP ENCLOSED TYPE 04 POLE COPPER JOINT TYPE | SLE-200 | |

| 144 | Enclosed Current Collector 4pole 40A | CURRENT COLLECTOR TROLLEY 40AMP 4 POLE | SLECC-4P-40 | |

| 145 | Enclosed Current Collector 5pole 40A | CURRENT COLLECTOR TROLLEY 40AMP 5 POLE | SLECC-5P-40 | |

| 146 | Enclosed Current Collector 4pole 70A | CURRENT COLLECTOR TROLLEY 70AMP 4 POLE | SLECC-4P-70 |

|

| 147 | Enclosed Current Collector 5pole 70A | CURRENT COLLECTOR TROLLEY 70AMP 5 POLE | SLECC-5P-70 | |

| 148 | Enclosed BOLTED JOINT | BOLTED JOINT | SLE-BJ |

|

| 149 | Enclosed JOINT COVER | JOINT COVER | SLE-JC | |

| 150 | Enclosed HANGER CLAMP | HANGER CLAMP | SLE-HC | |

| 151 | Enclosed END POWER FEED | END POWER FEED | SLE-EPF | |

| 152 | Enclosed CENTER POWER FEED | CENTER POWER FEED | SLE-CPF | |

| 153 | Enclosed END CAP | END CAP | SLE-EC | |

| 154 | Enclosed TOWING ARM AND BRACKET | TOWING ARM AND BRACKET | SLE-TAB | |

| 155 | Enclosed CURRENT COLLECTOR SHOE | CURRENT COLLECTOR SHOE | SLE-CCS |

|

Cost Comparison of DSL Busbars For Overhead Cranes

Steel Busbar

GI DSL Busbar

Aluminium DSL Busbar

Copper DSL Busbar

Electrical performance of DSL Busbars for Overhead Cranes

Steel Busbar

Low

GI Busbar

Moderate

Aluminium Busbar

High

Copper Busbar

Extreme

Different types of Joints for DSL Busbars

Bolt Type Joint

Pin Type Joint

Weld Type Joint

Rivet Type Joint

Busbar Protection

Protection from Short Circuits

In a three phase power delivery system, a minimum of three parallel DSL Busbars will be used to deliver power to the crane machinery. The gap between the DSL Busbars is an important parameter to avoid short circuits.

If there is a short circuit, the current will rise until the protection device kicks in.

This very high current will heat the DSL Busbars and will cause mechanical stress to the busbar as well as its

support units.

Protection from Human Touch

We only recommend insulated DSL Busbars, because like every other

electrical circuit, DSL Busbars need to be protection from human touch. No live or HOT sections are exposed

to the external environment.

Safe distance should also be maintained between two parallel DSL Busbars. Insulation will also help in

prevention of short circuit in the presence of foreign material touching two DSL Busbars.

Lifetime cost of Busbar

Installation Design

The design of the electrical system will play a major role in the installation price. The design of installation should focus on minimizing the time required to install the busbar and all its supporting components ,should minimize maintenance time,should provide easy and safe access to the maintenance and installation personnel. A well designed electrical system ,will allow for connections and disconnections in the future without stopping the production of a factory. The design should also allow for extensions to the busbar if required.

Cost of Installation

Cost to erect the busbar to the particular height, complexity of the busbar installation. Time to install all the number of supporting components such as joints, brackets,pins,etc play a major role in installation cost.

Recurring Cost

Maintenance cost of a busbar will be reduced if the busbar is used correctly. Using the busbar at lower working temperatures and not overstressing the DSL Busbars will cause the DSL Busbars to increase their life and reduce the maintenance costs.

Energy Cost

The amount of voltage drop in a busbar will affect the cost of energy you pay . Selecting the right conductor size will greatly minimize the voltage drop.As the weight of material increases the cost of the busbar increases, and the cost of energy decreases.

End of Life Cost

At the End of Life of the system, the DSL Busbars and its supporting components have to be removed.The cost of material used for the DSL Busbars will be of significant value. As the cost of metal increases the cost of material used for the busbar might appreciate. All other supporting plastic components will have to be recycled.Keeping all these points in mind, you can get a very practical view of the overall cost of a busbar system.

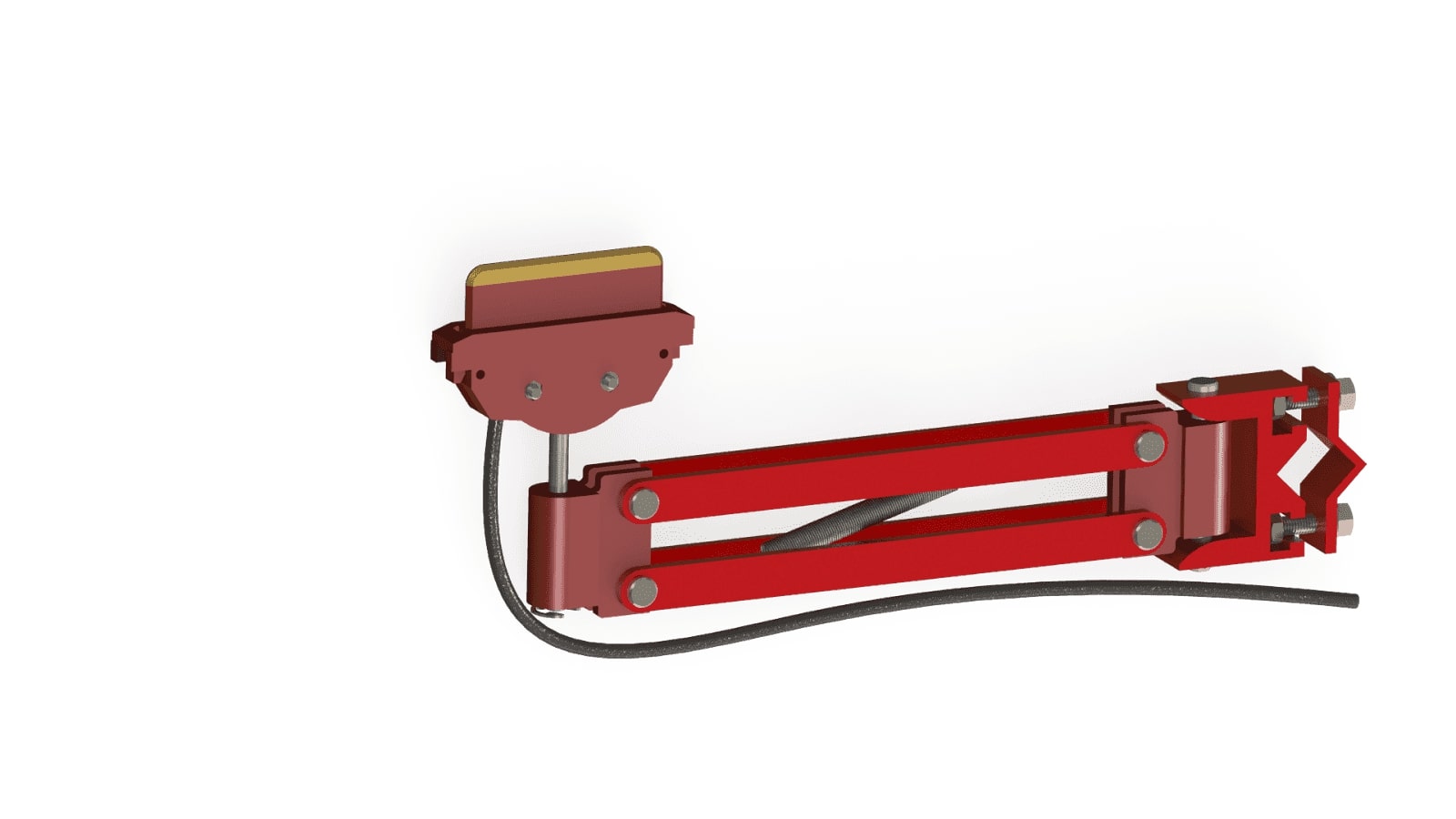

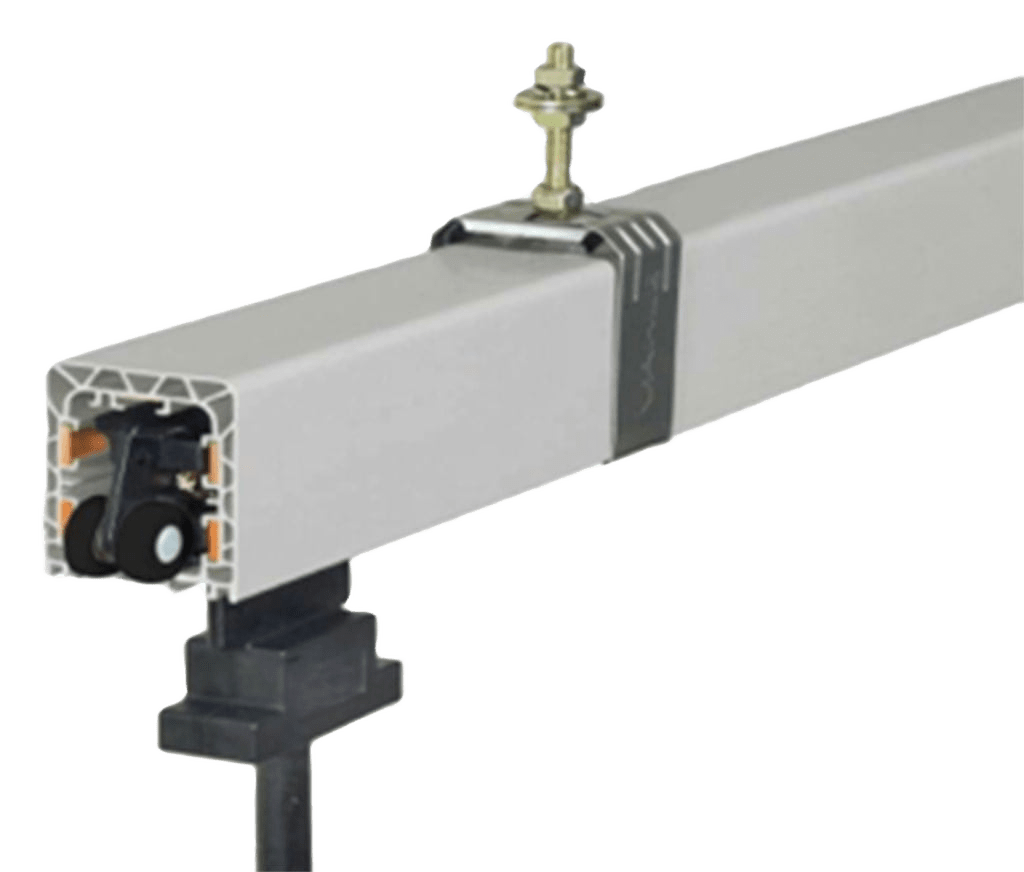

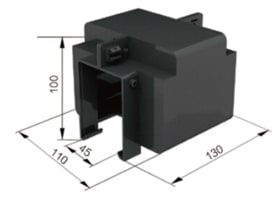

What is the Current collector of DSL Busbars?

One key component of DSL Busbars is the current collector, which is used to collect the electrical current from the conductor rail and transfer it to the moving equipment.

Current collectors are typically made of a copper-based material and come in various shapes and sizes depending on the application. They are designed to be in constant contact with the conductor rail, ensuring a reliable transfer of power and signals as the moving equipment travels along the busbar system.

Current collectors also come with additional features such as spring-loaded arms that maintain constant contact with the conductor rail, even in bumpy or uneven terrain.

Proper maintenance and inspection of current collectors are crucial for ensuring a safe and reliable operation of the DSL Busbar system. Wear and tear can occur over time, leading to decreased performance and potentially hazardous conditions. Regular inspections and replacement of worn or damaged current collectors can help prevent accidents and equipment failure.

Current Collectors come in 60 Ampere , 125 Ampere and 250 Ampere rating. Two Current Collectors can be used in Tandem to be used for higher current requirements and for expansion assemblies.

Design Considerations

When selecting current collectors for DSL busbars, several factors need to be considered, including:

Electrical Conductivity - Current collectors must be made of a material that has excellent electrical conductivity to ensure the efficient flow of current.

Corrosion Resistance - DSL busbars are often used in harsh environments, such as data centers or industrial plants. As a result, current collectors must be made of a material that is resistant to corrosion and oxidation.

Thermal Conductivity - Current collectors must be able to transfer heat away from the electrical system to prevent overheating.

Contact Resistance - The contact resistance between the current collector and the busbar must be as low as possible to reduce energy loss and heat generation.

Copper Current Collectors - Copper is the most commonly used material for current collectors in DSL busbars. Copper has excellent electrical conductivity and thermal conductivity, which makes it ideal for use in high current applications. Copper current collectors are also highly resistant to corrosion and oxidation, making them a durable and reliable choice.

These current collectors use a spring-loaded mechanism to maintain constant contact with the conductive rail, ensuring that electrical signals and power are efficiently transferred.

The sliding copper current collector consists of a copper head that slides along the conductive rail, and a spring-loaded mechanism that ensures continuous contact between the copper head and the rail. The spring-loaded mechanism applies a constant force to the copper head, ensuring that it maintains contact with the rail even when there are small variations in the rail height or movement.

The spring-loaded mechanism is designed to provide a constant force that allows the current collector to move along the rail without losing contact. This ensures that the electrical signal or power is continuously transmitted without any interruptions. The amount of force applied by the spring-loaded mechanism can be adjusted to suit the specific requirements of the application.

The copper head is designed to minimize the contact resistance between the collector and the rail. This is achieved by using high-quality copper with a low contact resistance and ensuring that the copper head is smooth and clean. This helps to reduce the voltage drop and ensures that the electrical signal or power is efficiently transferred.

Sliding copper current collectors are commonly used in applications where there is a need to transfer electrical power and signals between stationary and moving components. These applications include cranes, hoists, and other types of machinery that require electrical power to be transmitted from a stationary power source to a moving load.

Voltage Drop

Voltage drop of a busbar is very important parameter to consider.In laymans terms -

the amount of voltage not reaching the desired equipment from the power supply = Voltage Drop.

It is highly dependent on the resistance of the busbar being used and the amount of current being consumed.

Temperature also affects the voltage drop to some degree.

List of some common spare parts for DSL busbars

Current collectors: These are the components that make contact with the conductor and transmit electrical current. They are available in a variety of designs including sliding, rolling, and fixed. The type of current collector used will depend on the application.

PVC Insulators: These are used to separate the conductor from the housing and other components. They are typically made of high-quality insulating materials such as PVC.

End caps: These are used to seal the ends of the busbar system and prevent moisture and dust from entering. They are typically made of durable materials such as plastic or metal.

Expansion joints: These are used to compensate for the thermal expansion and contraction of the busbar system. They are typically made of stainless steel and come in a variety of lengths and designs.

Joint covers: These are used to protect the joints between busbar sections from damage and corrosion. They are typically made of durable materials such as aluminum or stainless steel.

Fasteners: These are used to secure the busbar system to the mounting structure. They are typically made of high-strength materials such as stainless steel and are available in a variety of sizes and designs.

Bolts and nuts: These are used to fasten the various components of the busbar system together. They are typically made of high-strength materials such as stainless steel and come in a variety of sizes and designs.

Gaskets: These are used to seal the joints between busbar sections and prevent moisture and dust from entering. They are typically made of durable materials such as rubber or silicone.

DSL Busbar MS Web Brackets: These are used to support the weight of the DSL busbar system and ensure proper alignment. They are typically made of durable materials such as powder coated Mild Steel and come in a variety of sizes and designs.

It is important to note that the specific spare parts required will depend on the make and model of the DSL busbar system. It is always best to consult the manufacturer's documentation or seek the advice of a qualified technician to ensure that the correct spare parts are used.

Understanding the Importance of DSL Busbar for EOT Cranes at Anand Systems Engineering Pvt Ltd

At Anand Systems Engineering Pvt Ltd, we are more than just a manufacturer of electrical and mechanical parts for EOT cranes. We pride ourselves on being innovators in the industry, as seen through our comprehensive collections and informative blog posts. One of our game-changing products is our DSL Busbar for EOT (Electric Overhead Traveling) cranes, a crucial component that ensures the smooth operation of these large machines. To better understand its function, let's delve a bit deeper into what DSL Busbar is and why it's vital for EOT cranes.

The Role of DSL Busbar

A DSL (Down Shop Lead) Busbar is essentially the lifeline of an EOT crane. It supplies power to the crane during its movement across the shop, allowing it to transport heavy loads from one place to another. This seemingly simple part plays a significant role in the overall operation of the crane.

Here at Anand Systems Engineering Pvt Ltd, we offer a variety of DSL Busbar systems suitable for different environments and needs. Among them,the Safelink M, Safelink V, and Safelink Enclosed are some of the top choices for our clients. Take some time to learn about these offerings on our Busbar page and explore the best fit for your EOT crane.

The Impact of DSL Busbar on EOT Crane Performance

"The quality of a DSL Busbar system directly impacts the efficiency and performance of an EOT crane. Thus, investing in a high-quality busbar is not just an option, but a necessity."

While EOT cranes are robust and resilient, their optimal performance relies heavily on their individual parts, including the DSL Busbar. Hence, ensuring that your crane is equipped with a reliable Busbar system is paramount to its overall productivity.

Enhancing Crane Operation with Anand's Top-notch Products

At Anand Systems Engineering Pvt Ltd, our commitment to quality extends beyond DSL Busbars. We offer a wide range of products designed to optimize the operation of EOT cranes. This includes radio remote controls such as the Anand Remote, and advanced pendant solutions for easier crane management.

Moreover, we provide comprehensive crane control gear options, equipped with various types of brakes like thruster brakes, AC electromagnetic brakes, DC electromagnetic brakes, and disk brakes. The purpose of all these products is to ensure the safety and efficiency of your EOT crane operation.

Continuous Improvement and Innovation

At Anand Systems Engineering Pvt Ltd, we believe in continuous improvement. Did you know that we have a dedicated careers page? We are always on the lookout for passionate individuals to join our team. By welcoming diverse skills and expertise, we aim to continuously innovate and enhance our offerings to better serve the EOT crane industry.

Stay tuned for the second part of this article, where we will delve even deeper into the details of DSL Busbars, illustrating the importance of their maintenance, and how Anand Systems Engineering Pvt Ltd addresses common challenges. Don't forget to visit our About Us page to learn more about our company's journey in the industry before reaching out through our Contact Us page.

Be sure to explore all the resources we have to offer on our website and make informed decisions regarding your EOT crane's infrastructure and maintenance.

Investing in Anand Systems' DSL Busbar for EOT Cranes: A Smart Move for Optimal Performance

Involved in the robust world of EOT cranes, we understand their intricacies at Anand Systems Engineering Pvt Ltd. Having earlier discussed the importance of DSL Busbar for these machines, let's now explore how maintenance of these components works and how we respond to common challenges.

DSL Busbar Maintenance: A Crucial Aspect

Maintenance of DSL Busbars is just as important as choosing a high-quality one. Neglecting this aspect can lead to decreased efficiency and potential safety hazards. Anand Systems Engineering Pvt Ltd continues to stress the significance of regular maintenance to prolong the lifespan of your DSL Busbar and, in turn, your EOT crane.

Here are some tips to keep in mind:

- Regularly inspect the DSL Busbar for any signs of wear and tear.

- Ensure the cleanliness of the busbar; dust and grime can hamper its performance.

- In cases of damage or malfunction, reach out to professionals immediately.

Please follow our blog post for helpful insights into boosting the performance and durability of your crane components.

Anand Systems' Solution to Common DSL Busbar Challenges

While DSL Busbars are exceptionally durable, they sometimes might face issues due to environmental factors or operational glitches. But fret not, as we at Anand Systems address these challenges with innovative solutions like the Safelink W.

Equipped with cutting-edge technology, our DSL Busbars are designed to withstand harsh operational conditions, ensuring unhampered functions. Moreover, our team of experts is always ready to provide prompt and efficient customer service and support.

Anand Systems: Your Partner in Excellence

At Anand Systems Engineering Pvt Ltd, we do not just provide products; we offer solutions. Beyond our exceptional DSL Busbar and Collection, we have also established industry knowledge through our blog, offering insights into subjects like crane safety measures and industrial IoT in cranes, amongst others.

Besides, we are committed to enhancing crane operations with our advanced Radio Remote Control Solutions and sophisticated Pendant collections. You can find detailed guides on our products in our downloadable catalogues, such as the Anand Radio Remote Control Catalog and Anand Pendant Catalog.

At Anand Systems Engineering, we also strive to make a difference in the world of crane operations with our innovative Crane SCADA solutions. We ensure that we stay ahead in the game, adopting the latest technologies and trends in the industry.

Join the Journey with Anand Systems Engineering

As a leading player in the field, we invite you to join us in our journey towards seamless and efficient crane operations. Visit our Careers page and become part of a team that is driven by innovation, fueled by passion, and committed to excellence. For any inquiries or more information, feel free to Contact Us.

No matter what your needs may be, from DSL Busbars to advanced crane control gear, Anand Systems Engineering Pvt Ltd promises to deliver quality, efficiency, and unrivaled customer service. Finally, remember to stay abreast of industry trends, updates, and practical tips by regularly visiting our informative Blog.